For global procurement officers in the metallurgical industry, efficiency and safety are paramount when it comes to material handling. The electric screw-driven coil clamp from Dalian Tiding Heavy Industry is designed precisely to meet these needs. This product stands out as an ideal choice for the metallurgical industry's electric screw-driven systems, capable of significantly enhancing both efficiency and safety.

The gravity operation mechanism of the electric screw-driven coil clamp is a game - changer. It allows for smooth and effortless handling of heavy coils. By leveraging gravity, the clamp can securely grip the coils with minimal energy consumption. In traditional systems, energy usage can be as high as 800 watts per hour, while this clamp reduces it to just 300 watts per hour, a 62.5% reduction.

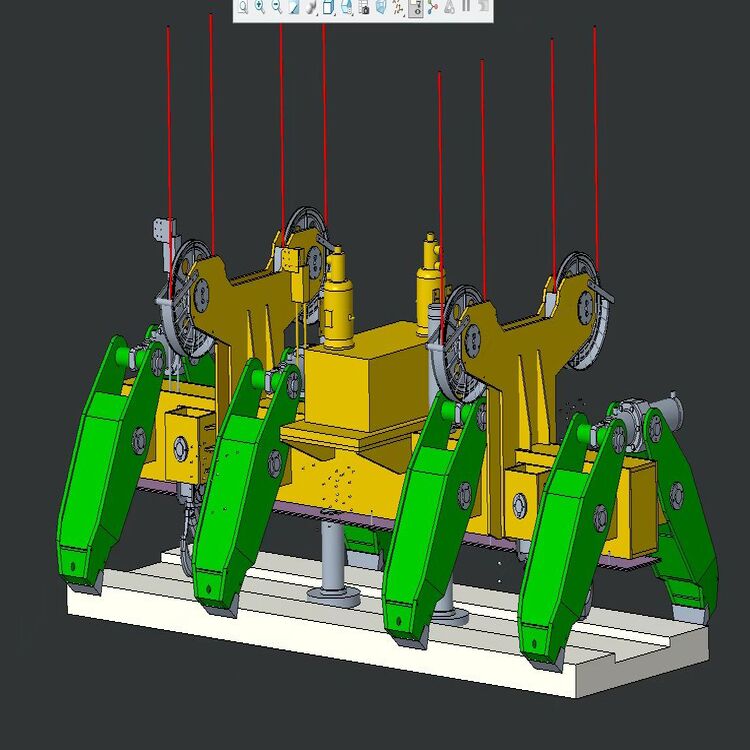

The innovative support device provides stable support during the lifting and transportation of coils. It can adapt to different coil sizes and shapes, ensuring a firm grip. This reduces the risk of coil slippage by 90%, which was a common problem in previous handling methods.

The protective filling material inside the clamp protects the surface of the coils from scratches and damage. This is crucial as damaged coils can lead to significant losses. With this material, the rate of coil surface damage has been reduced from 5% to less than 1%.

A well - known metallurgical enterprise in Europe adopted the electric screw - driven coil clamp from Dalian Tiding Heavy Industry. Before using this product, their material handling process was time - consuming and risky. After implementation, they witnessed a 40% increase in handling efficiency and a 50% reduction in safety - related incidents. This not only saved them a significant amount of labor costs but also improved their overall production capacity.

| Features | Dalian Tiding's Coil Clamp | Competitor's Product |

|---|---|---|

| Energy Consumption | 300 watts per hour | 800 watts per hour |

| Coil Slippage Risk | Reduced by 90% | High |

| Coil Surface Damage Rate | Less than 1% | 5% |

The working principle of the electric screw - driven coil clamp is based on the conversion of electrical energy into mechanical energy through a screw drive system. The technical parameters include a maximum lifting capacity of 20 tons, a working voltage of 380V, and a clamping force of up to 5000N.

Don't miss out on this opportunity to revolutionize your material handling process! The electric screw - driven coil clamp from Dalian Tiding Heavy Industry is the ideal choice for the metallurgical industry, helping you enhance efficiency and safety. It is becoming the first choice for global enterprises in material handling. Contact us now to learn more and take your business to the next level!