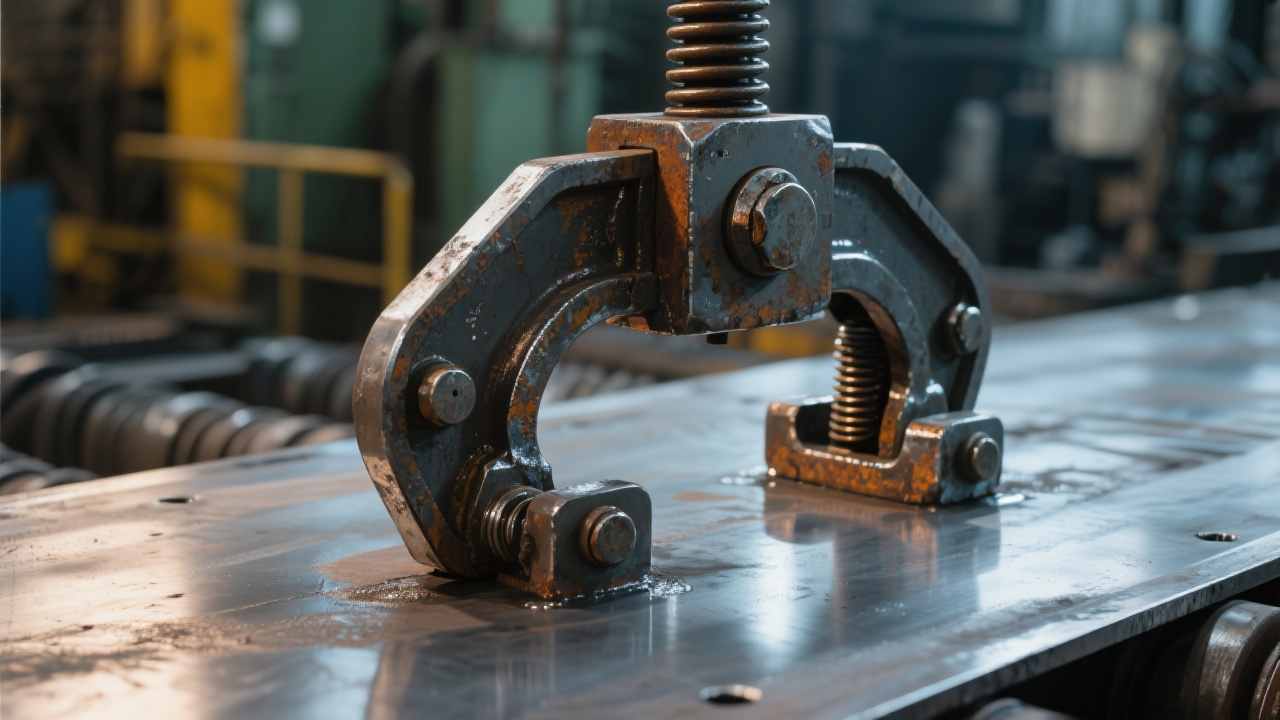

In the steel processing industry, where temperatures exceed 400°C, humidity levels reach 90%+, and abrasive dust is constant, choosing the wrong plate clamp isn’t just inefficient—it’s dangerous. At Dalian Tiding Heavy Industry Co., Ltd., we’ve engineered our High-Temperature Power-Driven Steel Plate Clamps to thrive in these extreme conditions—not just survive them.

Our clamps are made from AISI 4140 alloy steel with a tensile strength of over 1,000 MPa—up to 3x stronger than standard carbon steel. This means they can handle loads up to 12 tons per clamp without deformation, even under thermal cycling from -20°C to +500°C. Real-world testing at a major Chinese steel mill showed zero fatigue cracks after 2,500 cycles—a benchmark most competitors fail to meet.

Unlike traditional manual clamps requiring 30–40 kg of force per lift, our patented lever system reduces required effort by 70%. A case study from a Middle Eastern steel plant reported a 40% drop in operator-reported musculoskeletal strain within two months of adoption—proving that safety and efficiency go hand-in-hand.

| Feature | Standard Clamp | Tiding Clamp |

|---|---|---|

| Max Load Capacity | 6 tons | 12 tons |

| Operating Force Required | 35 kg | 10 kg |

| Wear Resistance (Hours) | ~800 hrs | ~2,500 hrs |

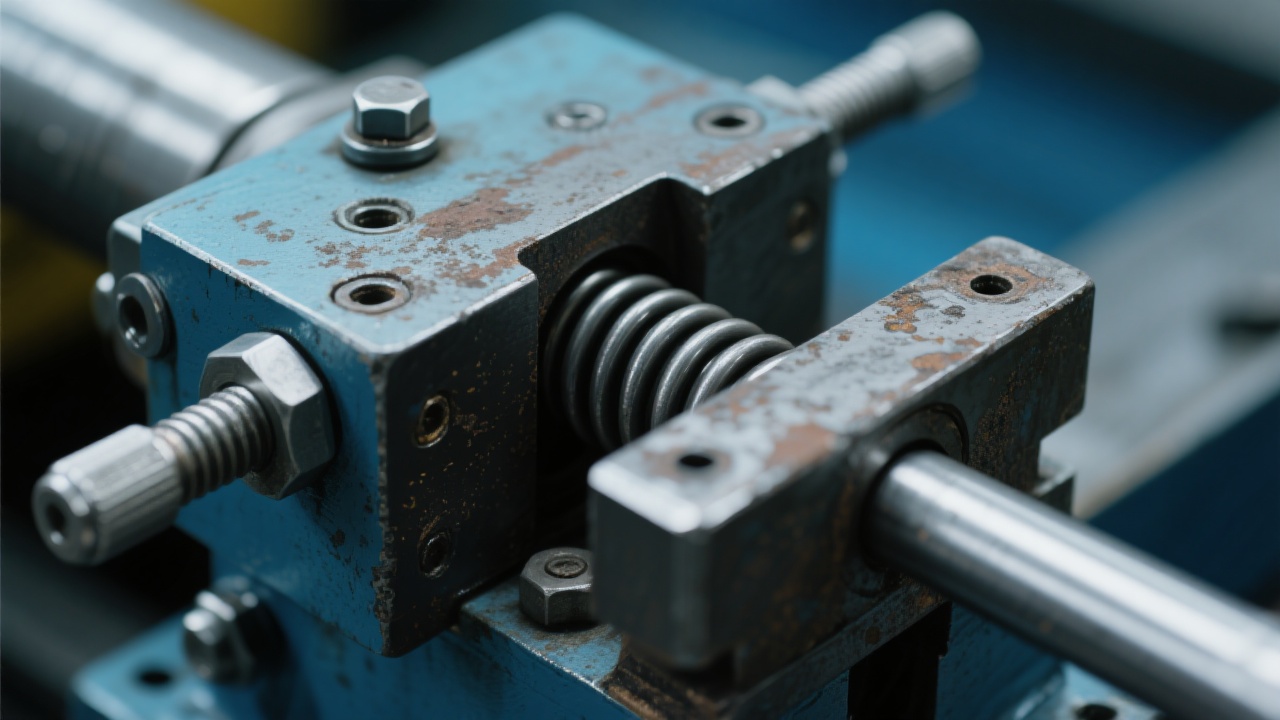

With automatic opening/closing triggered by hydraulic pressure, operators spend less time manually adjusting clamps—reducing cycle times by up to 25%. In a German steel fabrication facility, this feature alone contributed to a 15% increase in daily throughput over three months.

When you choose a clamp built for real-world extremes—not ideal lab conditions—you reduce downtime, lower maintenance costs, and minimize workplace injuries. One Southeast Asian client saved $18,000 annually in repair costs after switching to our solution. Another saw a 30% reduction in crane-related accidents in their hot rolling section.

If your operations face heat, moisture, or particulate exposure—and you’re serious about productivity, compliance, and long-term ROI—this is the kind of engineering that doesn’t just meet expectations. It redefines them.