Handling heavy metal plates at port terminals and warehouses presents critical safety and operational efficiency challenges. The transportation of plates weighing from several tons up to 500+ tons demands equipment capable of providing secure grip and reliable performance. Traditional lifting mechanisms often fall short in meeting these requirements, exposing operators and assets to risks such as slippage, damage, and downtime.

Industries like metal smelting, port logistics, and storage face significant bottlenecks related to material handling. Typical issues include:

Given these challenges, deploying a high-performance clamping device designed specifically for heavy plate lifting is indispensable to assure safety and optimize workflow.

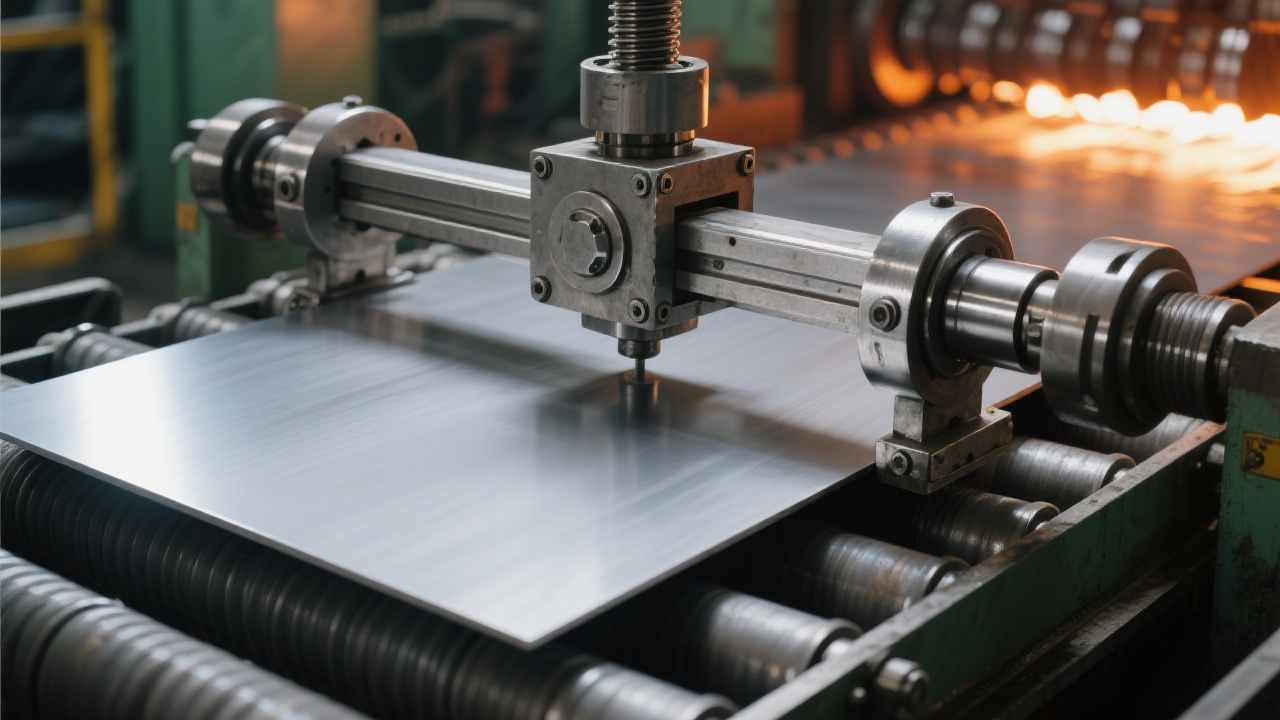

Developed with cutting-edge metallurgy and engineering, the plate clamp from Dalian Taiding Heavy Industry combines superior material strength and innovative mechanical design to address port terminal lifting challenges seamlessly.

| Feature | Specification |

|---|---|

| Material | High-strength alloy steel |

| Load Capacity Range | 8 tons to 550 tons |

| Drive Types | Hydraulic, pneumatic, manual lever options |

| Safety Features | Integrated clamping force and limit switches |

| Operation Principle | Mechanical leverage ensuring secure and smooth grip |

This versatile clamp design adapts effortlessly to various lifting environments. Its high-strength alloy steel composition grants enhanced durability and wear resistance, significantly extending service life under rigorous port and warehouse conditions.

The plate clamp has been successfully integrated into multiple metal smelting plants and port logistics centers, demonstrating tangible benefits:

For instance, a leading global steel producer reported a dramatic increase in handling throughput after deploying these clamps, successfully managing plate weights upwards of 400 tons with unmatched reliability.

The clamp’s modular design enables customization for a broad range of capacities and usage scenarios. Available with hydraulic systems for heavy lifting, pneumatic for rapid cycle tasks, or manual levers for simpler operations, it fits diverse operational needs.

Enhanced safety is ensured through dual sensor feedback controlling clamping pressure and positional limits. This not only protects the load but also the lifting rig and adjacent personnel.

In warehouse environments where frequent plate repositioning is required, the clamp’s rapid engage/disengage mechanism cuts downtime, directly supporting higher throughput and inventory turnover.

Ready to enhance your plate handling safety and efficiency? Discover how Dalian Taiding Heavy Industry’s plate clamp can revolutionize your operations today.