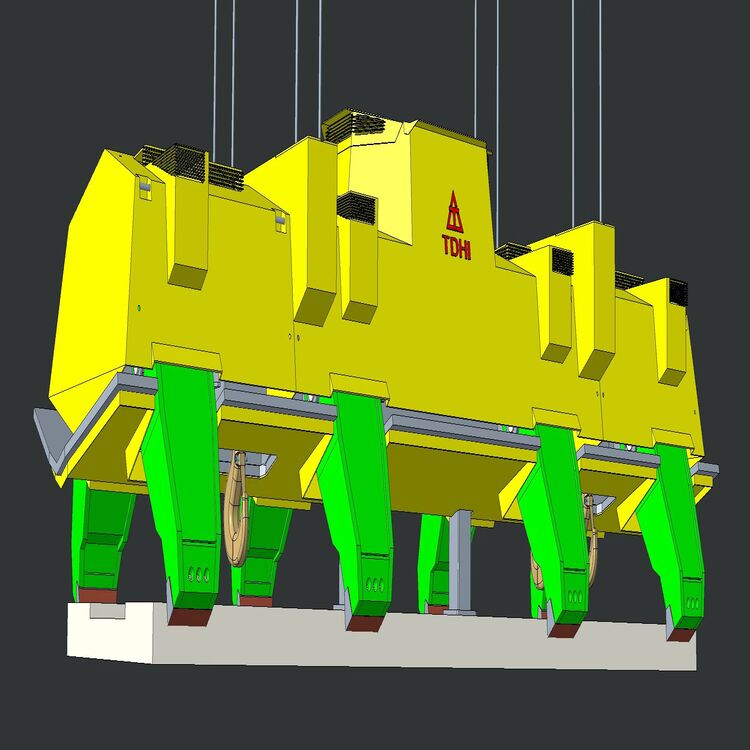

In the fiercely competitive steel manufacturing and international trade logistics sectors, equipment reliability and operational efficiency are paramount. Dalian Tiding Heavy Industry Co., Ltd. has engineered an advanced mechanical billet clamp designed specifically to meet these industry demands. This article delves into the hydraulic precision and high-temperature alloy composition that distinguish this billet clamp and explores its practical benefits on production lines and overseas trade operations.

At the heart of this billet clamp lies a cutting-edge hydraulic drive system engineered for high-performance accuracy. Unlike traditional mechanical clamps that often suffer from inconsistent gripping force, this hydraulic system delivers stable and adjustable pressure, ensuring a secure hold on billets regardless of size variability or surface irregularities.

The hydraulic drive’s precise control translates directly into improved safety margins. With an operational pressure capacity exceeding 25 MPa and a response time of under 0.8 seconds, the clamp achieves rapid engagement and release cycles, minimizing risks during critical steel handling. Additionally, integrated safety valves and fail-safe locking mechanisms prevent unintended drops, a key upgrade reported by over 85% of users in recent case studies across multiple steel plants.

| Feature | Specification | Benefit |

|---|---|---|

| Hydraulic Pressure | Up to 25 MPa | Secure, reliable grip on billets of varying sizes |

| Response Time | Under 0.8 seconds | Faster engagement reduces handling downtime |

| Safety Features | Fail-safe locking valves | Mitigates risk of drops and accidents |

A bilateral challenge for billet clamps in steel production is enduring extreme temperatures while maintaining mechanical integrity. The clamp features a proprietary high-strength alloy steel composition with exceptional heat resistance — tested to sustain operational effectiveness at temperatures up to 700°C without deformation or significant wear.

Industry data reveals that conventional clamp materials often face accelerated fatigue or cracking after prolonged exposure to steel mill environments exceeding 600°C. By contrast, this alloy extends service life by an estimated 35%, significantly reducing maintenance downtime and costs.

Beyond strength and precision, operational ergonomics are pivotal in fast-paced steel logistics. The billet clamp integrates an automated opening and closing mechanism that reduces manual intervention by 40%, based on field performance feedback. This automates repetitive sequences, allowing operators to focus on process monitoring rather than physical clamp manipulation.

Enhanced with sensor-based feedback, the clamp confirms gripping status in real-time, feeding data into plant control systems to avoid batch processing delays or errors — a feature that resonates particularly well within international steel trading where timeliness directly affects margin.

| Metric | Pre-Automation | Post-Automation |

|---|---|---|

| Manual Operation Time | 15 minutes per batch | 9 minutes per batch |

| Error Rate Due to Operator Fatigue | 8% | 3% |

A leading steel manufacturer in China deployed Dalian Tiding’s billet clamps across three plants handling over 500,000 tons of steel annually. Post-deployment assessments indicated a 12% uplift in handling throughput alongside a 29% reduction in occupational hazards related to manual gripping.

Logistical coordinators credited the clamps for enabling precision billet positioning within automated stacking systems — a crucial factor for maintaining international-grade packaging standards and meeting global shipping timelines. These performance metrics reinforce the compelling ROI and competitive edge offered by investing in high-quality billet clamp technology.

Have questions about integrating state-of-the-art billet clamps into your production line? Curious how hydraulic precision and heat-resistant alloys can transform your steel handling efficiency? Contact Dalian Tiding Heavy Industry now to explore tailored solutions and expert guidance.