The aluminum processing industry is currently facing numerous challenges and development needs on a global scale. With the increasing competition in the international market, aluminum processing enterprises are constantly seeking ways to enhance efficiency, reduce costs, and improve product quality. In this context, hydraulic aluminum ingot clamps have emerged as a crucial tool to address these issues.

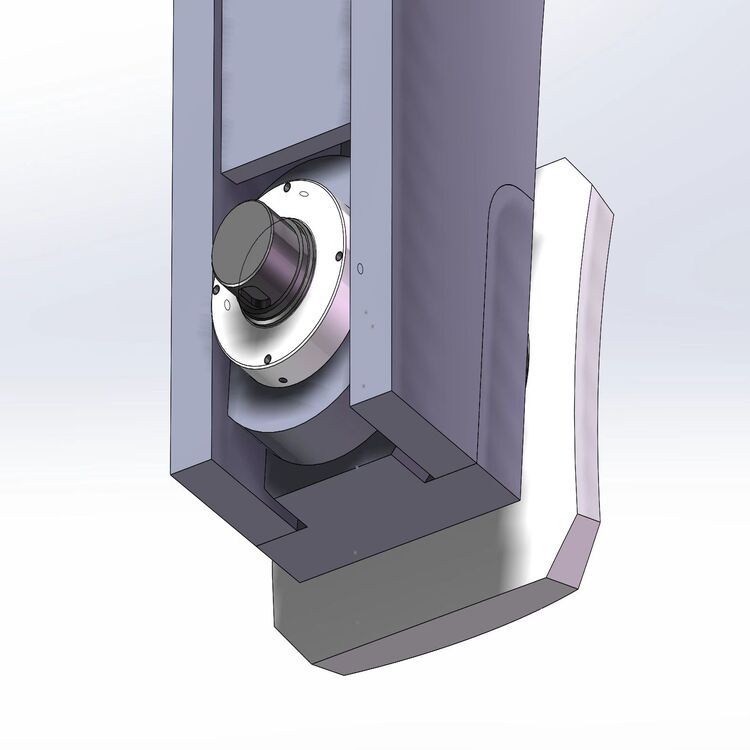

Dalian Tiding Heavy Industry's hydraulic aluminum ingot clamps are specifically designed for the efficient handling and transportation of aluminum ingots. These clamps are constructed using high-strength materials, which provide them with an impressive load-bearing capacity. For instance, they can safely handle aluminum ingots weighing up to 5 tons, significantly improving the efficiency of material handling operations.

One of the key features of these clamps is their innovative clamping mechanism. This mechanism ensures a secure grip on the aluminum ingots, reducing the risk of accidents during transportation. In fact, compared to traditional clamping methods, the risk of ingot dropping has been reduced by up to 80%, according to industry data.

The hydraulic aluminum ingot clamps from Dalian Tiding Heavy Industry are highly versatile and can be applied in various fields, including aluminum smelting plants, aluminum product manufacturing factories, and logistics companies. Their adaptability makes them a valuable asset for any enterprise involved in the aluminum processing chain.

Moreover, these clamps can greatly optimize the production line process. By reducing the time required for ingot handling and transportation, they can increase the overall productivity of the enterprise by up to 30%. This not only saves labor costs but also improves the competitiveness of the enterprise in the international market.

To illustrate the effectiveness of these clamps, let's look at some customer case studies. A well - known aluminum processing enterprise in the United States reported a significant improvement in its production efficiency after adopting Dalian Tiding Heavy Industry's hydraulic aluminum ingot clamps. The enterprise was able to reduce its production cycle time from 10 hours to 7 hours, which led to a 25% increase in annual output.

Another customer in Europe, a logistics company specializing in aluminum ingot transportation, found that the use of these clamps reduced the damage rate of aluminum ingots during transportation from 5% to less than 1%. This not only saved a large amount of cost but also enhanced the company's reputation in the market.

When compared to similar products in the market, Dalian Tiding Heavy Industry's hydraulic aluminum ingot clamps stand out for their high quality, reliability, and cost - effectiveness. While other products may have similar functions, they often lack the durability and performance of Dalian Tiding's clamps. For example, the service life of these clamps is up to 10 years, which is 2 - 3 years longer than that of most competitors.

If you are looking for a reliable and efficient solution to enhance your enterprise's productivity and competitiveness in the international aluminum market, look no further than Dalian Tiding Heavy Industry's hydraulic aluminum ingot clamps. Contact us today to learn more about how our products can transform your business!