In the global metallurgical industry, reliable and efficient material handling is paramount to operational success. Titanium Ding Heavy Industry’s Motorized Screw-Driven Coil Clamp emerges as a transformative solution empowering enterprises to streamline workflows while safeguarding personnel and products. Designed with precision and built for robust performance, this advanced clamp is fast becoming the preferred choice of leading companies worldwide.

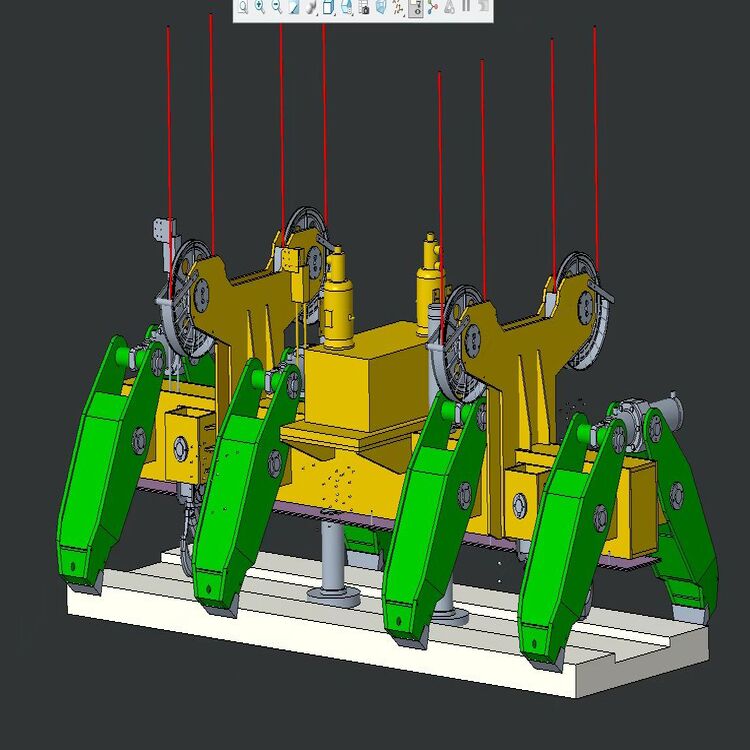

Tailored specifically for heavy industries such as steel manufacturing, metal rolling, and coil processing plants, the Motorized Screw-Driven Coil Clamp addresses core challenges faced by equipment procurement managers, plant engineers, and operations supervisors. These professionals seek solutions that guarantee smooth handling of heavy coils with minimal manual intervention and maximal protection against material damage.

The clamp’s innovative motorized screw-driven mechanism ensures precise and effortless opening and closing actions. Unlike traditional hydraulics or pneumatic systems that may involve complex maintenance and inconsistent force application, this mechanism provides uniform and controllable gripping pressure. This design reduces downtime by 25% on average in steel coil transfer operations—significantly elevating plant throughput.

Safety remains a non-negotiable priority. Titanium Ding’s clamp incorporates high-quality protective cushioning pads that significantly reduce coil surface damage. This feature minimizes costly rework and rejects, while protecting workers from injury caused by slipping or dropped material. Moreover, the operator-friendly design with gravity-assisted functions reduces fatigue, promoting safer operational practices.

One standout feature is its innovative adjustable support device, engineered to accommodate coils of varying diameters ranging from 500 mm up to 2500 mm. This flexibility empowers facilities to handle diverse product ranges without investing in multiple clamps, yielding over 30% cost savings in equipment procurement.

An implementation at Shandong Steel Plant demonstrated a 40% reduction in coil handling time and a 15% decline in product damage after adopting the Motorized Screw-Driven Coil Clamp. Operators reported enhanced handling confidence due to the smooth power transmission and cushioned gripping elements. As a result, production schedules improved and workplace incidents decreased year-over-year.

| Feature | Specification |

|---|---|

| Clamping Mechanism | Motorized screw-driven system |

| Coil Diameter Range | 500 mm to 2500 mm |

| Gripping Force Control | Adjustable, uniform pressure |

| Protective Padding | High-grade impact absorption material |

| Power Supply | Electric, 380V / 50Hz standard |

Titanium Ding Heavy Industry’s commitment to quality, innovation, and customer-centric design renders their Motorized Screw-Driven Coil Clamp a global benchmark in material handling equipment. Its superior operational efficiency and enhanced safety features enable enterprises to optimize logistics workflows while minimizing risks and costs.

As a consequence, more than 150 metallurgical companies worldwide have integrated this advanced clamp into their production lines, reporting measurable improvements in operational metrics within six months of deployment.

Contact Titanium Ding Heavy Industry today to discover how the Motorized Screw-Driven Coil Clamp can revolutionize your workflow, maximize safety, and improve cost-efficiency.

Get Your Customized Solution Now