Material handling in the metallurgical industry is a critical process that demands both precision and safety. As global manufacturers seek to optimize their operations, the need for reliable and efficient equipment has never been more pressing. Dalian Tidaung's motorized screw-driven coil clamps have emerged as a game-changer, offering a combination of advanced design, superior performance, and unmatched safety features.

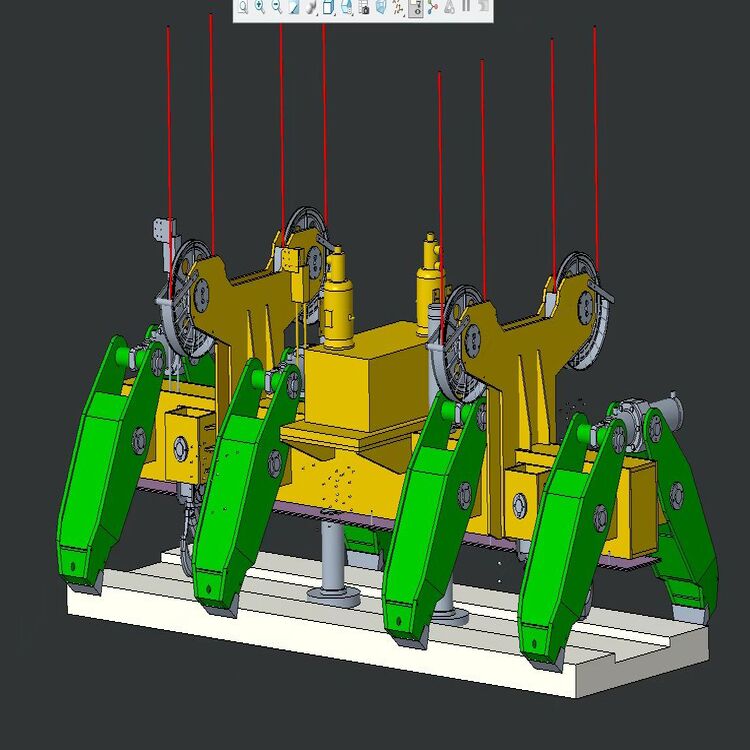

Dalian Tidaung’s motorized screw-driven coil clamps are engineered to meet the rigorous demands of the metallurgical sector. The product combines cutting-edge technology with practical engineering, ensuring that it delivers consistent performance across various applications.

The gravity-assisted operation mechanism significantly enhances efficiency by reducing manual effort. This feature allows the clamp to automatically adjust its grip based on the weight and size of the material, minimizing the risk of misalignment or damage during lifting and transporting.

With an innovative support system, the coil clamp can adapt to different coil diameters without requiring extensive adjustments. This flexibility ensures that the clamp can be used across a wide range of materials, from thin sheets to heavy slabs, making it a versatile solution for any metallurgical facility.

The use of high-quality protective filling material ensures that the clamping surface remains intact even under extreme conditions. This not only protects the material being handled but also extends the lifespan of the clamp itself, offering long-term value and reliability.

A leading steel manufacturing company in Southeast Asia faced significant challenges in efficiently managing its material handling processes. With the introduction of Dalian Tidaung’s motorized screw-driven coil clamps, the company saw a remarkable improvement in both operational efficiency and worker safety.

| Metrics | Before Implementation | After Implementation |

|---|---|---|

| Handling Time per Load | 12 minutes | 6 minutes |

| Incident Rate | 4 incidents/month | 0 incidents/month |

| Operator Fatigue Level | High | Low |

Compared to traditional hydraulic or manual clamps, Dalian Tidaung’s motorized screw-driven coil clamps offer several distinct advantages. They provide faster operation, greater precision, and require less maintenance. Additionally, the automated nature of the system reduces the need for manual intervention, which is especially beneficial in high-volume production environments.

The motorized screw-driven mechanism operates on a closed-loop control system, ensuring accurate positioning and consistent force application. This level of precision is essential when handling delicate or high-value materials. Furthermore, the clamp’s modular design allows for easy integration into existing material handling systems, reducing installation time and costs.

Dalian Tidaung has built a strong reputation for delivering high-performance, durable, and safe material handling solutions. Their commitment to innovation and quality has made them a preferred supplier for many global manufacturers. By choosing Dalian Tidaung, you are not just purchasing equipment—you are investing in a long-term partnership that values excellence and reliability.