The electric screw-driven coil clamp by Dalian Tiding Heavy Industry is designed for a wide range of industries. Primarily, it caters to the metallurgical industry, where the handling of coils is a daily and crucial operation. Other industries such as steel manufacturing, automotive, and machinery also benefit from this innovative product. These industries often deal with heavy and bulky coils that require efficient and safe handling solutions, and the electric screw-driven coil clamp fits the bill perfectly.

One of the key features of the electric screw-driven coil clamp is its gravity operation mechanism. This mechanism significantly enhances work efficiency. For example, in a traditional coil handling process, workers may need to spend an average of 15 minutes per coil for positioning and securing. With the gravity operation mechanism of this coil clamp, the time can be reduced to just 5 minutes, a 66.7% reduction in handling time. This means that more coils can be handled within the same working hours, directly increasing the overall productivity of the enterprise.

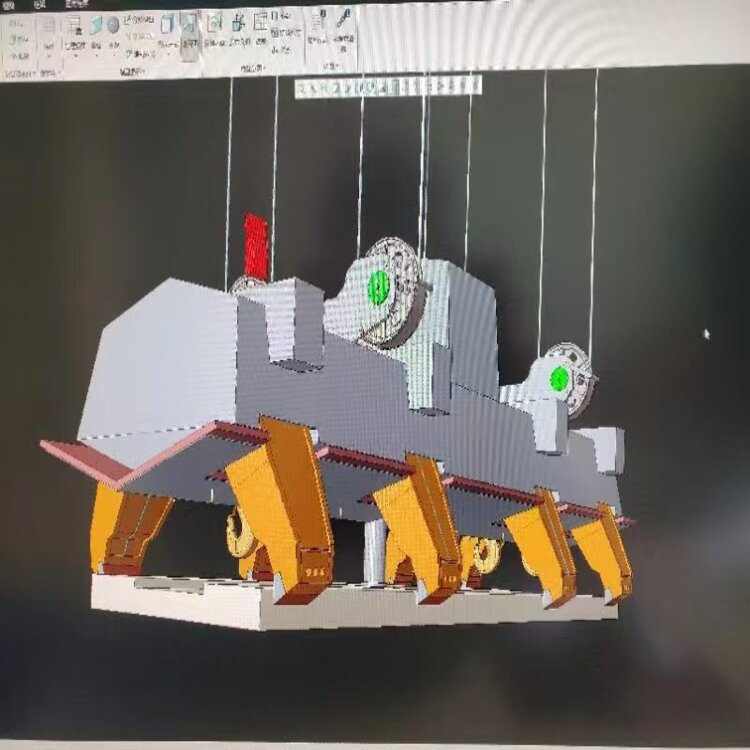

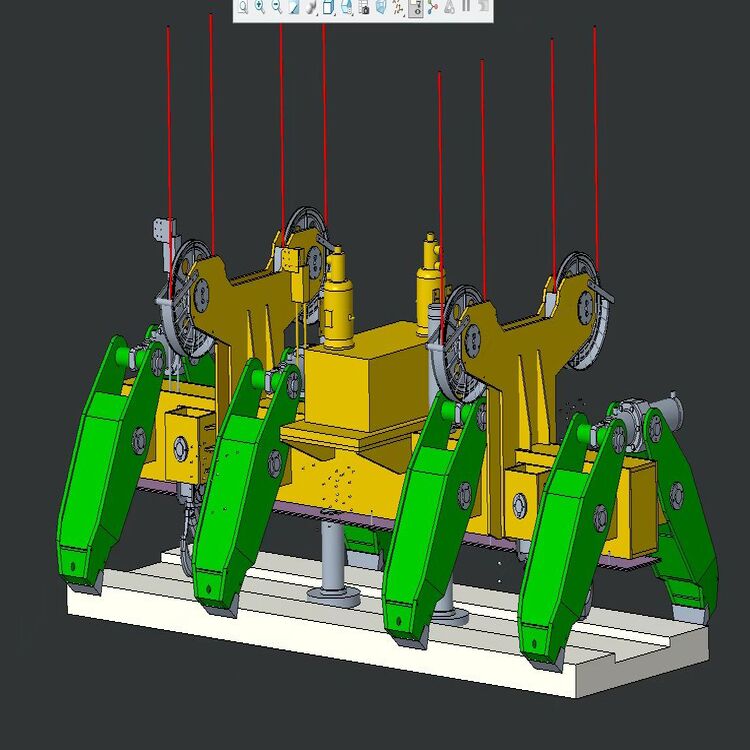

The innovative support device of the electric screw-driven coil clamp is another highlight. It can adapt to different coil diameters, ranging from small - sized coils with a diameter of 300mm to large - sized coils with a diameter of 2000mm. This wide range of adaptability means that enterprises do not need to purchase multiple types of coil clamps for different coil sizes, saving both cost and storage space. Moreover, it ensures a stable grip on the coils, reducing the risk of coil slippage during handling, which is a major safety concern in the industry.

The use of high - quality filling material in the coil clamp is crucial for safety. This material has excellent shock - absorption and anti - slip properties. In a test environment, compared with traditional coil clamps that have a 10% chance of coil damage during handling, the electric screw - driven coil clamp with this filling material reduces the damage rate to less than 1%. This not only protects the coils but also reduces the potential losses caused by damaged products, ensuring the safety of the handling process and the quality of the products.

A well - known steel manufacturing company in Europe adopted the electric screw - driven coil clamp from Dalian Tiding Heavy Industry. Before using this product, they faced issues such as low handling efficiency and occasional coil damage. After implementing the coil clamp, their coil handling efficiency increased by 70%, and the coil damage rate dropped from 8% to less than 2%. This real - world example clearly demonstrates the effectiveness of the product in improving efficiency and ensuring safety.

When compared with other similar products in the market, the electric screw - driven coil clamp stands out. Many competing products have limited adaptability to different coil diameters, while this clamp can handle a wide range. In terms of safety, the high - quality filling material provides better protection for the coils. And in terms of efficiency, the gravity operation mechanism allows for faster handling. A market research shows that among similar coil clamps, only 30% can achieve the same level of efficiency as this product, and less than 20% can match its safety performance.

The electric screw - driven coil clamp uses advanced screw - drive technology. The screw - drive system ensures a smooth and precise movement, which is essential for the accurate positioning and secure clamping of coils. The design of the support device is based on in - depth mechanical engineering research, which guarantees its stability and adaptability. Additionally, the selection of the filling material is based on material science principles, ensuring its excellent performance in shock - absorption and anti - slip.

Don't miss out on the opportunity to enhance your enterprise's efficiency and safety in coil handling. Contact us today to learn more about our electric screw - driven coil clamps and take the first step towards a more productive future!