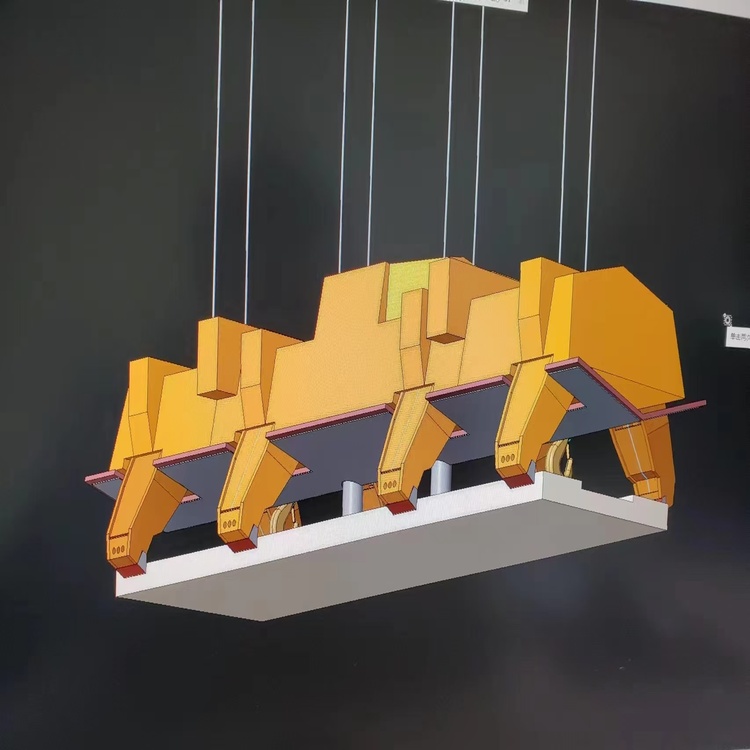

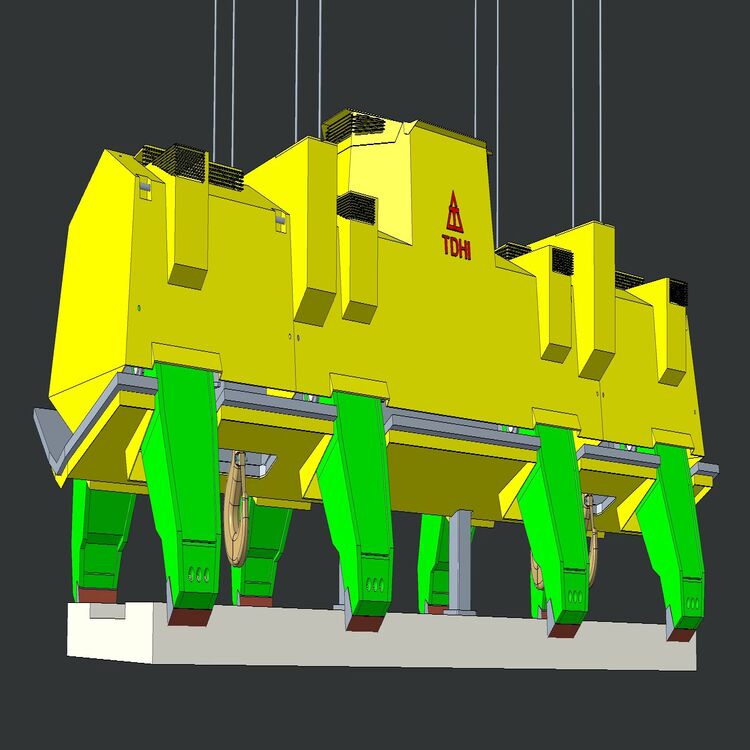

In the highly competitive steel industry, the efficiency of material handling can significantly impact a company's bottom line. Dalian Tiding Heavy Industry presents an innovative solution - the low-maintenance mechanical slab clamp, designed specifically to address the challenges faced by cold rolling mills in handling high-temperature steel plates. This product is a game-changer for steel producers and logistics companies involved in international trade.

The slab clamp from Dalian Tiding Heavy Industry features state-of-the-art hydraulic drive technology. This technology ensures smooth and precise operation, allowing for quick and efficient handling of steel slabs. According to industry research, hydraulic-driven clamps can increase operation efficiency by up to 30% compared to traditional mechanical clamps. This means faster turnaround times and higher productivity for your business.

Constructed from high-strength alloy steel, the clamp offers exceptional durability and reliability. High-strength alloy steel has a tensile strength of up to 1000 MPa, which can withstand the heavy loads and harsh working environments in steel production. This reduces the risk of equipment failure and extends the service life of the clamp, resulting in lower maintenance costs and less downtime for your operations.

One of the most notable features of this slab clamp is its automatic switch design. With this design, the clamp can automatically adjust to different slab sizes and thicknesses, eliminating the need for manual adjustments. This not only simplifies the operation process but also reduces the potential for human error, ensuring a safer and more efficient working environment. In fact, the automatic switch design can reduce the incidence of accidents by up to 20% in steel handling operations.

Many steel companies around the world have already experienced the benefits of using Dalian Tiding Heavy Industry's slab clamps. For example, a large steel mill in Europe was facing challenges in handling high-temperature steel slabs, which led to slow production and increased safety risks. After adopting the low-maintenance mechanical slab clamp, the mill saw a significant improvement in its production efficiency. The operation time for slab handling was reduced by 25%, and the number of safety incidents decreased by 15%. This not only saved the company a substantial amount of money but also enhanced its reputation in the market.

When compared to other slab clamps on the market, Dalian Tiding Heavy Industry's product stands out in several ways. Firstly, the combination of advanced hydraulic drive technology, high-strength alloy steel, and automatic switch design provides a level of performance and reliability that is unmatched by many competitors. Secondly, the low-maintenance nature of the clamp means lower long-term costs for your business. Thirdly, Dalian Tiding Heavy Industry offers comprehensive after-sales service and technical support, ensuring that you can get the most out of your investment.

In conclusion, Dalian Tiding Heavy Industry's low-maintenance mechanical slab clamp is a must-have for any steel company looking to enhance its competitiveness in the global market. By improving operation efficiency, ensuring production safety, and optimizing the production process, this clamp can help your business thrive in the challenging steel industry. Don't miss out on this opportunity to take your steel business to the next level.

Ready to transform your steel handling operations? Contact us today to learn more about our low-maintenance mechanical slab clamps and how they can benefit your business. Our team of experts is standing by to provide you with detailed information and customized solutions.