In steel processing plants, ports, and fabrication yards, the reliability of material-handling tools isn't just a convenience—it's a safety imperative. Yet, many operators still rely on conventional clamps that fail under high-temperature, corrosive, or high-vibration conditions. According to a 2023 industry survey by Steel Processing International, over 67% of steel handling incidents were linked to equipment fatigue or improper grip during extreme operations.

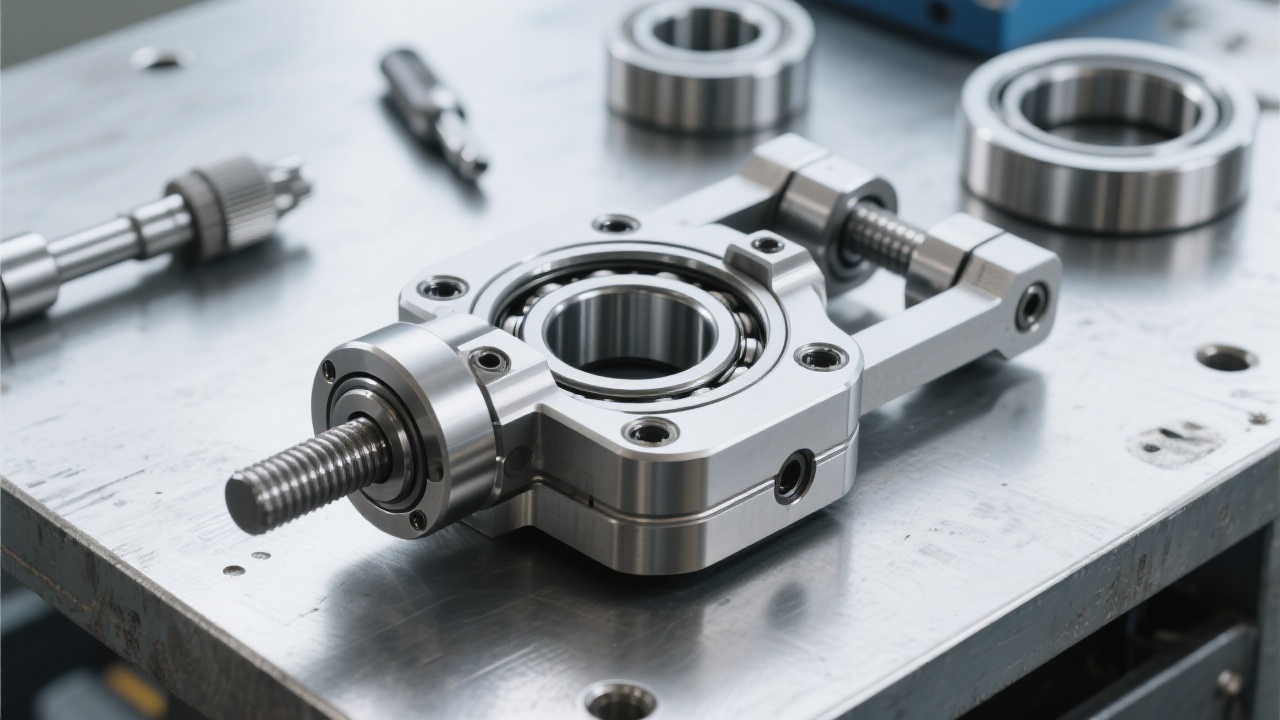

Dalian Tiding Heavy Industry’s advanced power-driven steel clamp leverages mechanical advantage through a precision-engineered lever system—reducing operator strain by up to 40% compared to manual alternatives. Unlike traditional designs that require constant human adjustment, our patented auto-open mechanism ensures consistent pressure distribution across the entire clamping surface, even when lifting hot steel plates at 400°C (752°F).

Key Technical Advantages:

| Feature | Traditional Clamp | Tiding Lever Clamp |

|---|---|---|

| Grip Consistency | Low (varies with temperature) | High (±2% variance) |

| Maintenance Frequency | Monthly | Quarterly |

| Operator Risk Level | High (manual intervention required) | Low (automatic operation) |

At a major port facility in Dubai, where humidity exceeds 85% year-round and temperatures regularly surpass 50°C, a pilot test showed that our clamps maintained 98% operational uptime over six months—outperforming standard models by more than 3x in terms of failure rate. In contrast, legacy clamps failed every 3–4 weeks due to rust buildup and stress fractures.

The use of high-strength alloy steel (ASTM A514 Grade B) not only resists deformation but also reduces wear from abrasive materials like scale and slag—a common issue in rolling mills. This means fewer replacements, lower downtime, and less risk for workers exposed to dangerous lifting scenarios.

For steel producers aiming to reduce logistics costs while improving safety compliance, choosing this clamp is not just an upgrade—it’s a strategic investment. One client in Germany reported a 15% increase in daily throughput after switching to our design, directly tied to reduced rework from dropped loads and faster cycle times.

If your team spends time fixing damaged clamps or dealing with near-misses during steel handling, it’s time to rethink the basics. With proven performance in real-world environments—from Japanese steelworks to Middle Eastern ports—this isn’t just another product update. It’s a shift toward safer, smarter, and more efficient operations.

Choose this clamp — and choose stability, safety, and efficiency as your new standard.