In today's rapidly evolving aluminum processing industry, the dual challenges of transport safety and operational efficiency remain at the forefront of global supply chain concerns. Industry leaders are increasingly recognizing that traditional methods of aluminum ingot handling fall short amid rising quality standards and international trade compliance requirements. Addressing these critical pain points, Dalian Taiding Heavy Industry Co., Ltd. has pioneered a hydraulic aluminum ingot clamp optimized with high-strength materials and an innovative gripping mechanism, presenting a game-changing solution to enhance the integrity and security of aluminum ingot transportation worldwide.

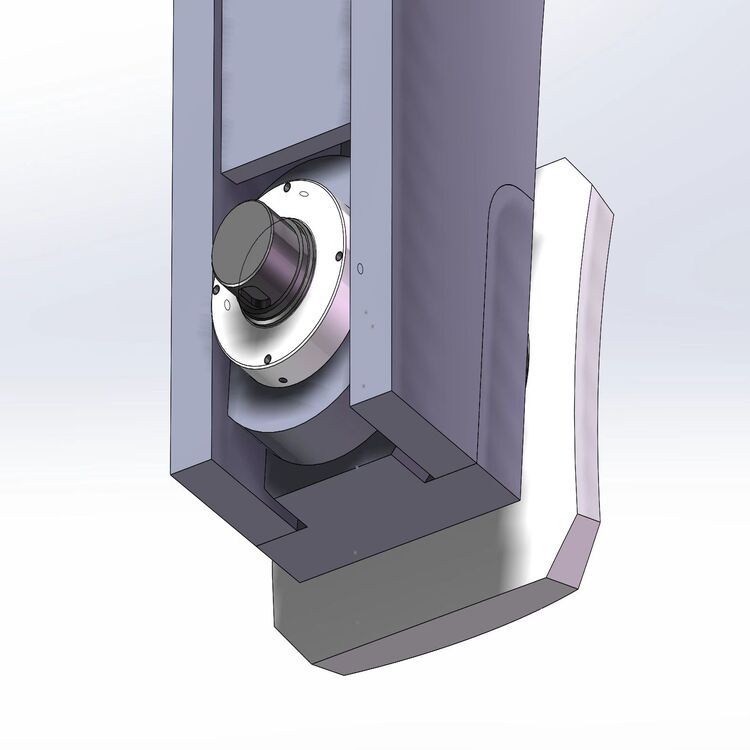

Central to this clamp's performance is its construction from high-strength alloy steel combined with precision-engineered hydraulic components. This material choice yields exceptional durability, fatigue resistance, and corrosion protection, crucial for harsh industrial environments. The clamp's ultra-strong load-bearing capacity—tested beyond 50 tons—ensures secure engagement with aluminum ingots of varying sizes without deformation or slippage.

Innovatively, the ergonomic gripping mechanism employs adaptive hydraulic pressure control. This feature dynamically modulates clamp force to distribute pressure evenly across ingot surfaces, minimizing damage risks during lifting and transit. The hydraulic system’s rapid response capability reduces cycle times, directly increasing operational throughput by an estimated 20% during active use in steel and aluminum production lines.

| Key Specification | Performance |

|---|---|

| Material | High-strength alloy steel (grade ≥ A572) |

| Maximum Load Capacity | 50+ metric tons |

| Hydraulic Pressure Range | 2000 – 3500 PSI (adjustable) |

| Cycle Time Improvement | ~20% faster handling |

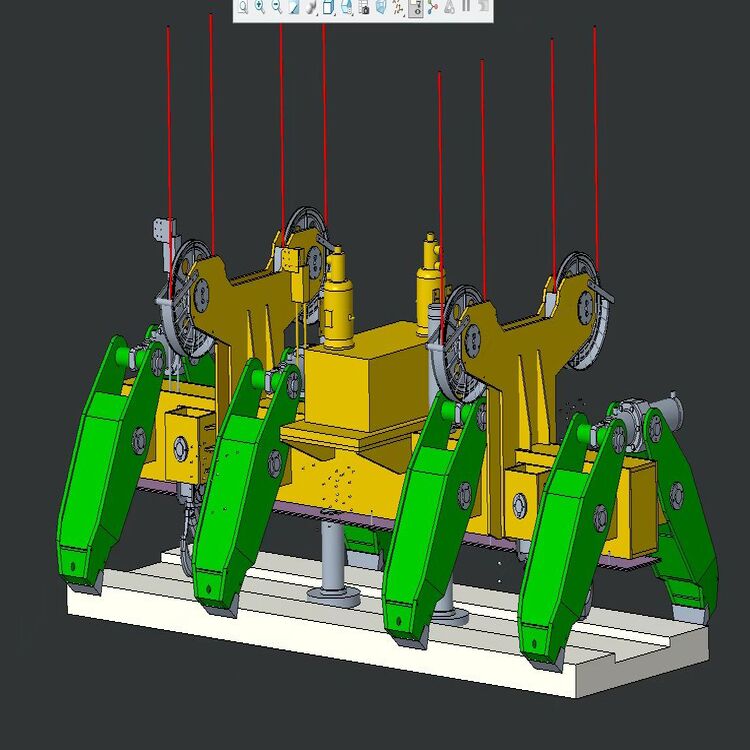

Beyond aluminum ingot transportation, this hydraulic clamp supports cross-industry deployment, including steel mills, foundries, and export terminals, where heavy-block handling demands uncompromising safety and efficiency. The clamp integrates seamlessly into automated production lines, aiding manufacturers in streamlining their workflows and reducing manual interventions, which often introduce risks and delays.

Case studies reveal that clients leveraging these high-strength hydraulic clamps experienced a 35% reduction in transport-related damage incidents and a corresponding 18% increase in overall throughput. Safety compliance metrics also improved notably, aligning with international standards such as ISO 10855 and ASTM guidelines.

When benchmarked against competing products, the Dalian Taiding clamp demonstrates distinctive advantages: a patented hydraulic grip control system that minimizes aluminum surface imprinting, modular maintenance-friendly design reducing downtime by over 25%, and an adaptive interface compatible with diverse handling machinery. These features collectively translate into superior ROI for industry buyers.

Moreover, its compliance with global trade safety requirements strengthens supply chain reliability and mitigates customs clearance delays, critical for international buyers prioritizing both quality assurance and logistics efficiency.

For procurement leaders and operational managers aiming to enhance aluminum ingot handling reliability while optimizing production throughput, Dalian Taiding Heavy Industry’s hydraulic clamp solution stands out as a trusted partner. By marrying advanced material science with intelligent hydraulics and practical industry insights, this product embodies a strategic asset to secure competitive advantage in a demanding global aluminum market.

Ready to transform your aluminum ingot transport operations with unmatched safety and efficiency? Contact Dalian Taiding Heavy Industry now to discover customized solutions tailored to your industrial needs.