In the aluminum processing industry, ensuring the secure and efficient handling of aluminum ingots remains a persistent challenge. Frequent issues such as ingot slippage, surface damage, and prolonged handling times not only increase operational costs but also dampen production throughput. To address these pain points, Dalian Taiding Heavy Industry has engineered an advanced hydraulic aluminum ingot clamp designed exclusively to elevate transportation safety and streamline workflow.

Aluminum ingots, due to their weight and shape, are prone to shifting during transport, leading to potential surface damage and even accidents in warehouses and production lines. Traditional mechanical clamps often suffer from inadequate gripping force and uneven pressure distribution, causing instability especially in multi-layer stacking environments.

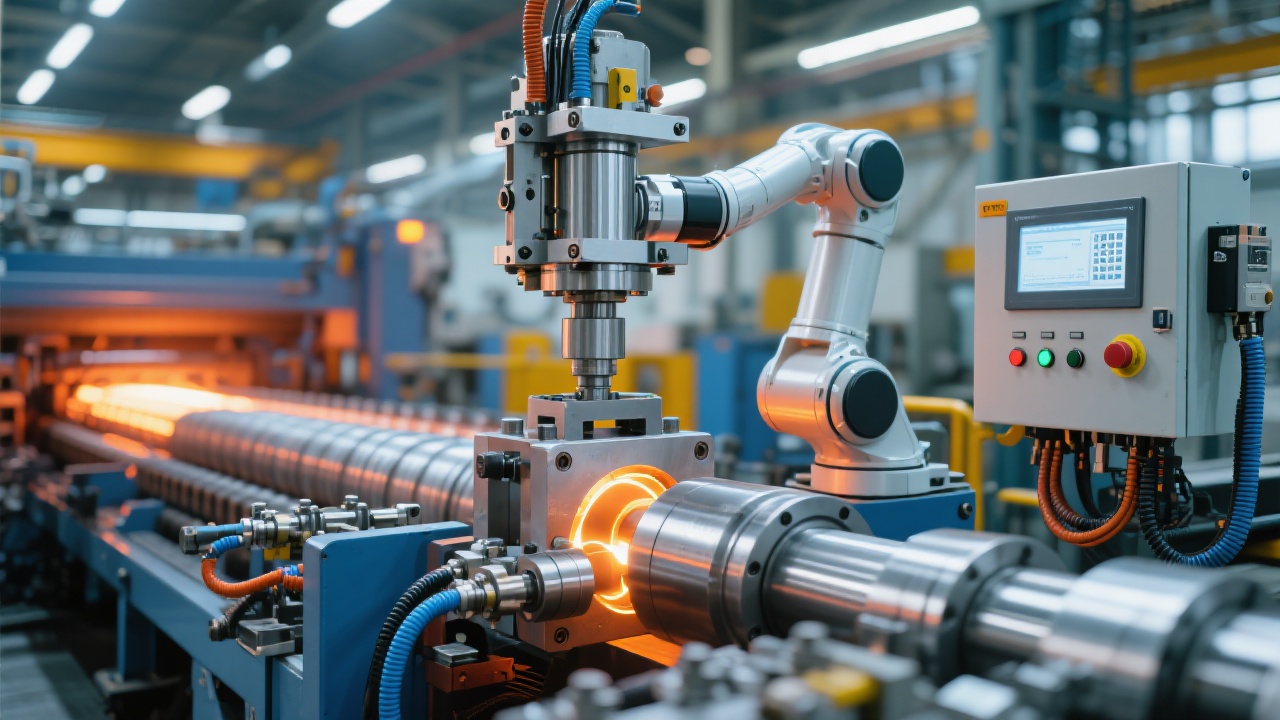

Moreover, the increasing demand for higher production rates and lean manufacturing underscores the need for equipment that not only secures loads effectively but also integrates seamlessly into automated processes.

The hydraulic aluminum ingot clamp from Dalian Taiding Heavy Industry distinguishes itself through several key features:

Dalian Taiding’s hydraulic clamps are designed for adaptability in various aluminum-related processes including:

By integrating these clamps, enterprises can expect a reduction in manual labor requirements, prevention of material wastage due to damage, and a more streamlined material handling process, ultimately improving line efficiency by an estimated 25% based on field data.

| Features | Hydraulic Clamp | Mechanical Clamp |

|---|---|---|

| Clamping Force Uniformity | > 95% precision, adjustable | Varies, often uneven |

| Maximum Load Capacity | Up to 5 tons | Up to 3 tons |

| Maintenance Frequency | Low; hydraulic systems designed for durability | High; mechanical wear parts require frequent replacement |

| Operational Safety | Integrated fail-safe and pressure controls | Limited safety features |

| Cost Efficiency Over Lifecycle | Higher initial cost, significantly lower operating costs | Lower upfront cost, higher long-term maintenance expenses |

A leading Southeast Asian aluminum extrusion company recently deployed our hydraulic clamp solution to replace their outdated mechanical clamps. Within six months:

These outcomes underscore how the innovative hydraulic clamping system contributes to operational excellence while fostering safer working conditions.

Elevating aluminum ingot transportation requires equipment that blends strength, precision, and reliability seamlessly. Dalian Taiding Heavy Industry’s hydraulic aluminum ingot clamps deliver this trifecta, making every transport “rock-solid” while injecting vital safety and efficiency into your aluminum processing chain. Whether your operation spans smelting, extrusion, or warehousing, investing in these clamps positions your business for durable competitiveness in global markets.

Have you encountered challenges in aluminum ingot transportation? Share your specific scenario with us, and we’ll provide three tailored industry cases to optimize your process.