In the steel industry, high - temperature environments pose significant challenges to steel plate handling. Steel companies often face low efficiency and high safety risks when moving steel plates under high - temperature conditions. For instance, the traditional handling methods are not only time - consuming but also expose workers to extreme heat, increasing the probability of accidents. Statistics show that in high - temperature steel plate handling operations, the accident rate can be as high as 15%, and the handling efficiency is only about 60% of that in normal temperature environments.

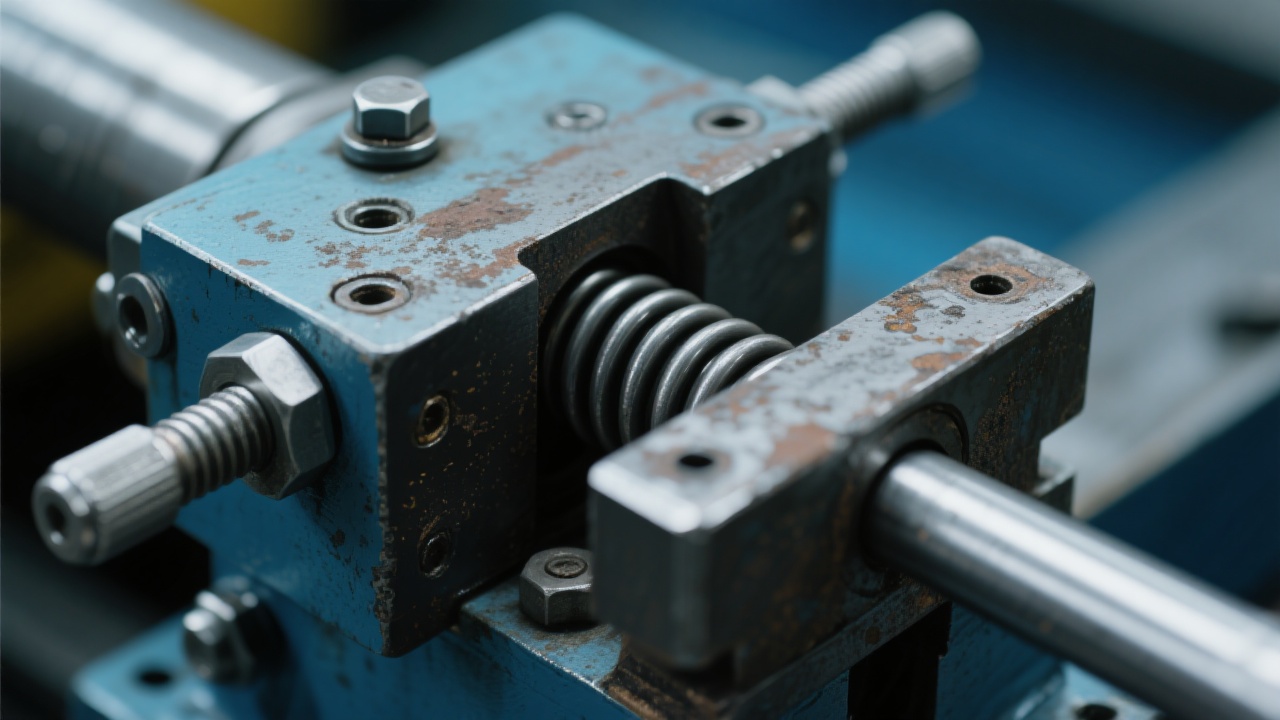

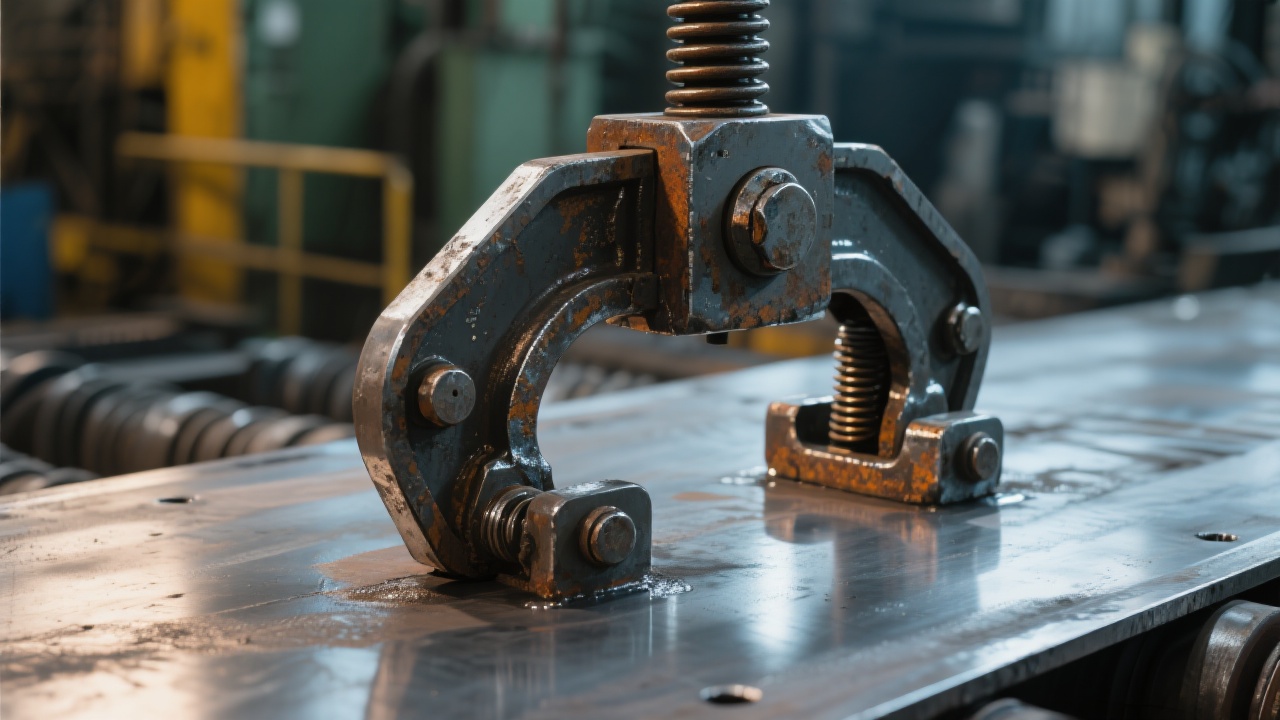

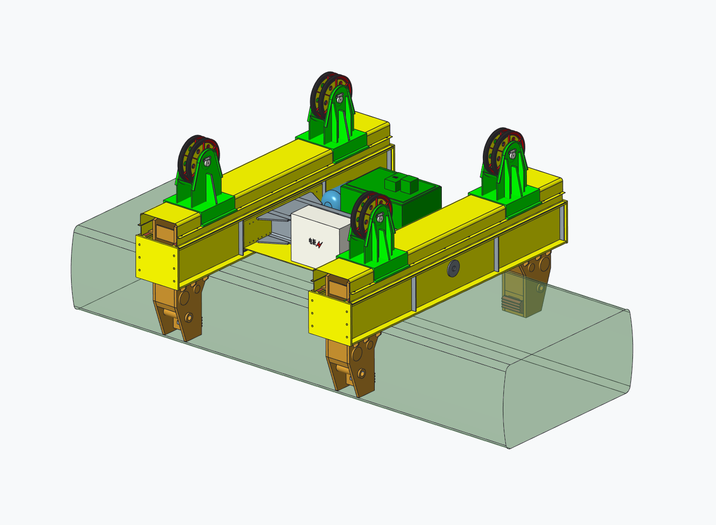

Dalian Tiding Heavy Industry's high - efficiency power - type steel plate clamps are designed to address these challenges. The clamps are made of high - strength alloy steel, which provides excellent durability and corrosion resistance. The innovative lever design allows for automatic grasping without external assistance. This unique mechanism enables the clamps to open and close automatically, ensuring stable operation and significantly improving the safety and efficiency of the handling process. Compared with traditional clamps, the load - bearing capacity of these clamps has increased by 30%.

In practical applications, such as in ports and steel mill workshops, these clamps can adapt to complex environments including humidity, high temperature, and dust. The high - strength alloy steel material is resistant to rust and wear, ensuring long - term use in harsh conditions. For example, in a port environment where steel plates are often exposed to seawater and high humidity, the clamps can maintain their performance without being affected by corrosion.

By using these clamps, steel companies can significantly reduce manual risks. The automatic grasping function eliminates the need for workers to operate in high - temperature areas for a long time, reducing the probability of heat - related injuries. In addition, the stable operation of the clamps reduces the risk of steel plate dropping during handling, further enhancing safety.

The high - strength alloy steel material and the innovative design of the clamps reduce the frequency of maintenance. Traditional clamps often require frequent replacement of parts due to wear and tear, but these clamps can operate stably for a long time, reducing maintenance costs by up to 40%.

Whether handling single - layer or multi - layer steel plates, these clamps can work efficiently. They can quickly grasp and release steel plates, increasing the loading and unloading efficiency by 50%. This improvement in efficiency not only shortens the handling time but also reduces the overall cost of the steel logistics process.

In the international trade scenario, the reliability of these clamps is crucial. Their ability to operate in complex environments and their high efficiency make them a competitive choice for steel companies. By using these clamps, steel companies can improve their overall competitiveness, reduce costs, and accelerate the growth of their export business. They can ensure the safe and efficient handling of steel plates during the international transportation process, which is essential for maintaining good business relationships with international customers.

Choose Dalian Tiding Heavy Industry's high - efficiency power - type steel plate clamps, and let your steel logistics be safer, more efficient, and more competitive. Don't miss this opportunity to transform your steel handling operations. Click here to learn more.