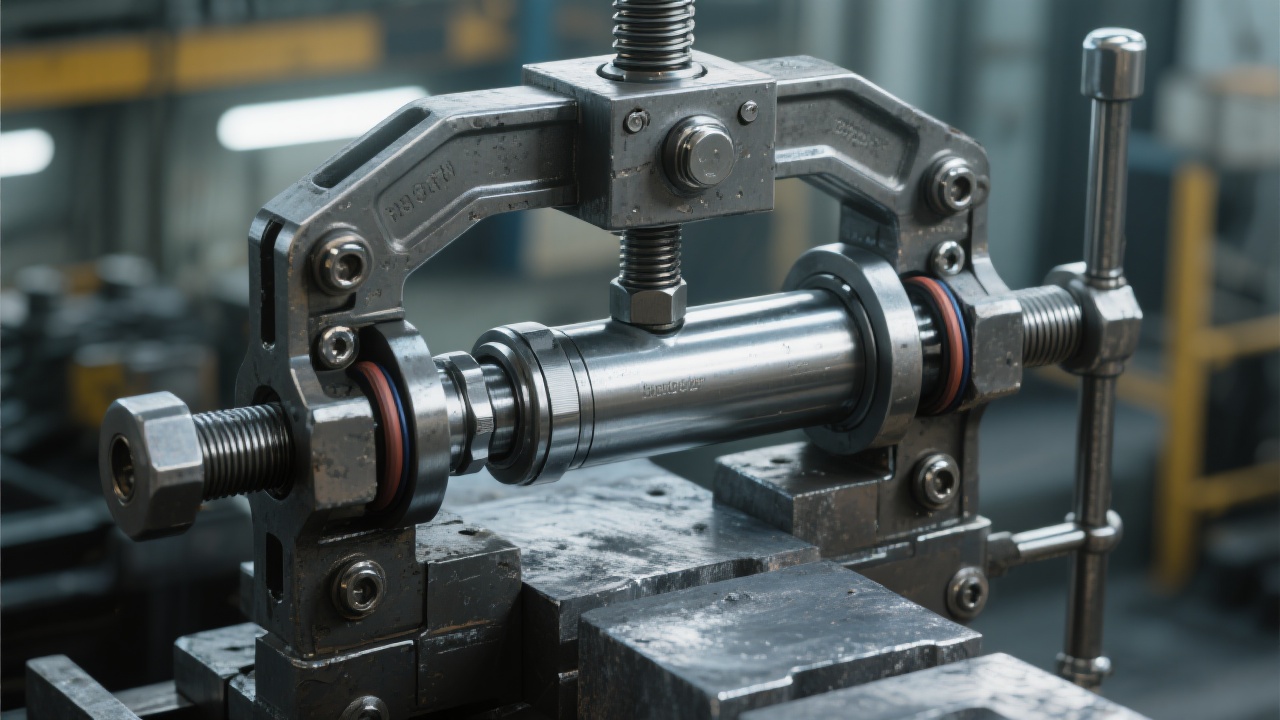

As a procurement decision-maker in the steel production industry, you're constantly on the lookout for reliable equipment that can enhance efficiency and safety in your operations. One such crucial piece of equipment is the high-wear-resistant slab clamp. But how do you choose the right one? This article will guide you through the process, analyzing the adaptability of materials to different working conditions and introducing you to a preferred solution from Dalian Tiding Heavy Industry.

You may have encountered several challenges when it comes to slab clamps. For instance, rapid wear is a common issue. Traditional clamps made of inferior materials can wear out quickly, leading to frequent replacements and increased costs. Moreover, safety accidents can occur due to the instability of clamps, which not only endangers the lives of workers but also disrupts production. Low efficiency is another pain point, as slow and unreliable clamping operations can bottleneck the entire production line.

Industry data shows that in steel production enterprises, approximately 30% of production delays are related to the poor performance of slab clamps, and the cost of replacing worn-out clamps can account for up to 15% of the annual equipment maintenance budget.

When choosing a slab clamp, the material is of utmost importance. High-strength alloy steel and ordinary carbon steel are two commonly used materials, but their performance in high-temperature working conditions varies significantly. High-strength alloy steel has excellent heat resistance and wear resistance. It can maintain its mechanical properties even in high-temperature environments, reducing the risk of deformation and wear. In contrast, ordinary carbon steel may lose its strength and hardness at high temperatures, making it less suitable for long-term use in high-temperature working conditions.

There are mainly two driving methods for slab clamps: pneumatic and hydraulic. Pneumatic clamps are relatively simple in structure and low in cost, but they have some limitations. For example, their stability is affected by air pressure fluctuations, and they require more frequent maintenance due to the wear of pneumatic components. On the other hand, hydraulic clamps offer better stability and higher clamping force. They can operate smoothly under heavy loads and are less affected by external factors. Although the initial investment in hydraulic clamps is higher, their low maintenance cost in the long run makes them a more cost-effective choice.

| Driving Method | Stability | Maintenance Cost |

|---|---|---|

| Pneumatic | Low (affected by air pressure) | High (frequent component replacement) |

| Hydraulic | High (stable under heavy loads) | Low (less component wear) |

Let's take a look at a real application case. A cold-rolling mill replaced its old slab clamps with Dalian Tiding Heavy Industry's low-maintenance hydraulic slab clamps. After using these clamps, the failure rate decreased by 60%, and the operation efficiency increased by 25%. This significant improvement not only reduced production downtime but also increased the overall productivity of the mill. The high reliability and efficiency of these clamps have made them the preferred choice for many cold-rolling mills.

When selecting a slab clamp, you should consider multiple aspects. In terms of material, choose high-strength alloy steel for high-temperature and heavy-load working conditions. For the driving method, hydraulic clamps are generally a better choice for their stability and low maintenance cost. In addition, pay attention to the structural design of the clamp. A reasonable design can ensure better clamping performance and longer service life. Don't forget about after-sales service. A reliable supplier should be able to provide timely technical support and maintenance services.

High-quality slab clamps not only improve production efficiency but also enhance safety. By reducing the risk of accidents, they create a safer working environment for your employees. Moreover, in the international market, reliable and efficient equipment can enhance your company's competitiveness. It shows your commitment to quality and safety, which can attract more international customers and help you expand your business overseas.

Are you ready to upgrade your slab clamps and take your steel production to the next level? Click here to learn more about Dalian Tiding Heavy Industry's high-wear-resistant slab clamps and how they can benefit your business!