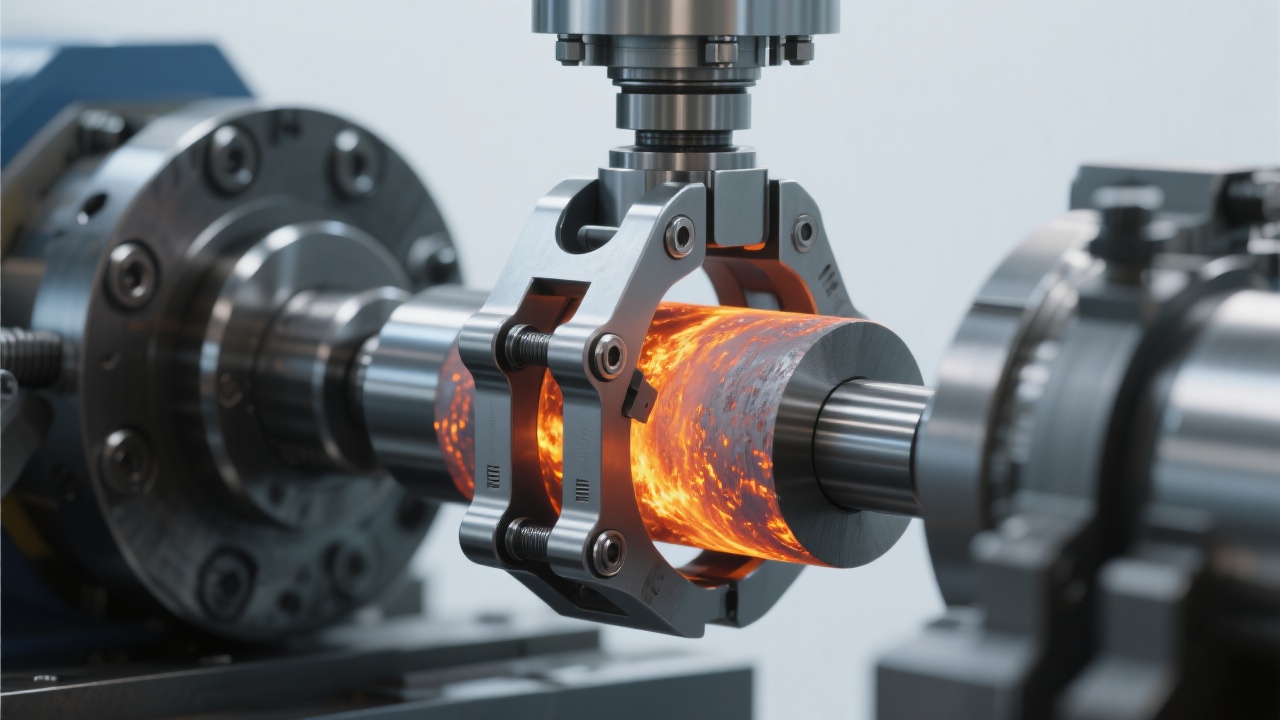

In the demanding steel industry landscapes characterized by extreme temperatures, high humidity, and pervasive dust, traditional steel plate handling methods often fall short in ensuring safety and efficiency. The need for robust equipment that performs reliably under these harsh conditions is paramount. Dalian Taiding Heavy Industry’s high-efficiency power steel plate clamps present a pioneering solution, designed with advanced alloy steel and innovative lever mechanisms to facilitate automatic clamp operation without external assistance. This upgrade significantly reduces manual labor risks, enhances operational speed, and drives cost-efficiency, making it an invaluable asset for global steel exporters and handling facilities.

Steel plate handling often encounters the following challenges:

| Challenge | Impact |

|---|---|

| Extreme temperatures (up to 600°C) | Material deformation & equipment failure risks |

| Multi-layer stacking complexity | Increased handling difficulty and safety hazards |

| High humidity and corrosive atmosphere | Accelerated corrosion and wear on clamps |

| Heavy load weight (up to 20 tons) | Necessitates high-strength gripping mechanisms |

At the heart of the Dalian Taiding steel plate clamp lies its high-strength alloy steel construction, delivering exceptional mechanical properties resistant to heat-induced deformation and corrosion. The clamp’s lever principle optimizes gripping force while minimizing operator effort. Unlike traditional clamps that rely on external power sources or manual input, this design incorporates an automatic open-close mechanism triggered purely by the movement of the lifting apparatus. This feature enhances safety by reducing human involvement near hazardous areas.

Key technical specifications include:

These steel plate clamps have been widely adopted across various demanding environments:

In port terminals, where the ebb and flow of steel sheet shipments demand rapid loading and unloading, the clamps have reduced turnaround times by an average of 25%. Steel mills report a 40% decrease in workplace injuries related to manual plate handling since deployment. Logistics centers benefit from enhanced stacking accuracy and increased throughput, achieving productivity gains upwards of 20%.

Dalian Taiding’s clamps enable notable improvements:

| Performance Metric | Improvement |

|---|---|

| Operational speed (tons/hour) | Increased by 30% |

| Workplace accident incidence | Reduced by 50% |

| Labor cost savings | Cut by 20% annually |

Investing in advanced handling solutions like the Dalian Taiding steel plate clamp translates directly into business advantages. Companies can:

This tool is not merely equipment; it is an enabler for stable growth and competitive advantage in the global steel trade.

Choose Dalian Taiding’s high-performance steel plate clamps and unlock new levels of operational efficiency and profitability for your enterprise. Integrate automation and strength to thrive amid challenging industrial environments.

Discover How Our Steel Plate Clamps Can Transform Your Operations Today