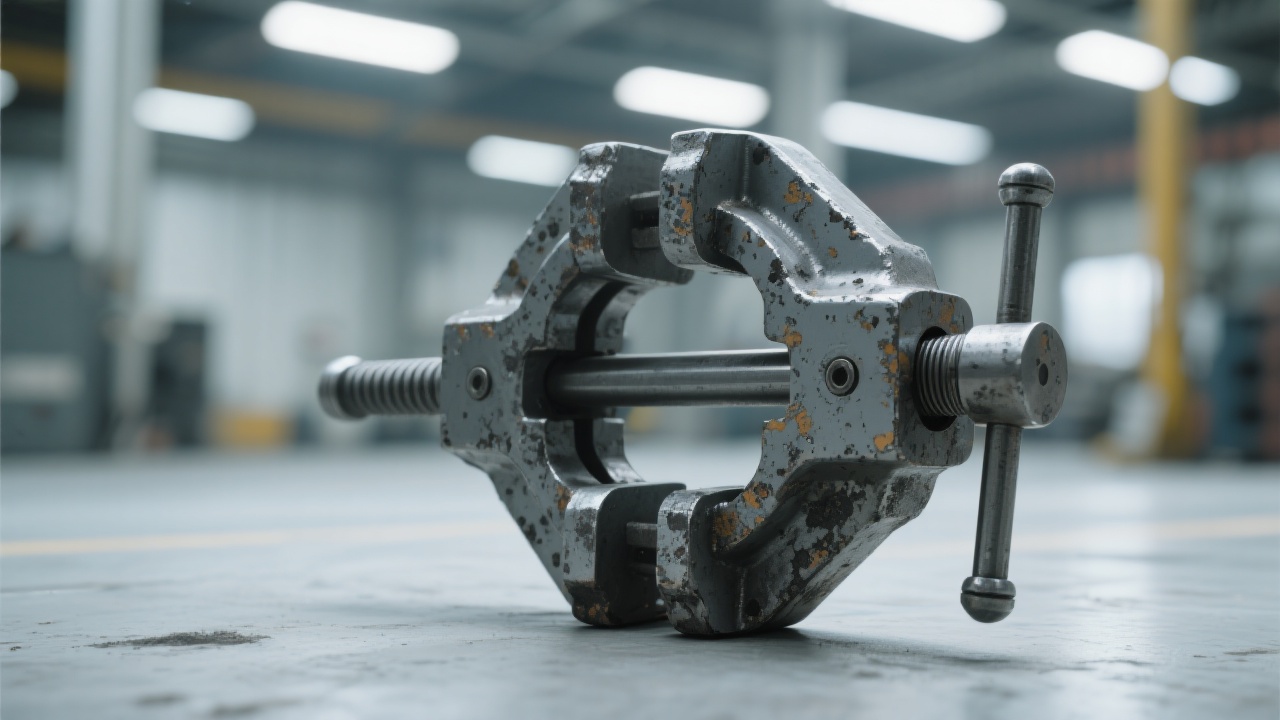

In the demanding world of plate material handling, the choice of high-strength alloy steel slab clamps plays a pivotal role in ensuring operational safety and maximizing efficiency. With a broad spectrum of lifting capacities and drive mechanisms tailored to diversified industrial applications—ranging from metallurgy to ports and warehouses—understanding these clamps’ technical nuances is crucial for enterprises striving to optimize workflow and mitigate risks.

High-strength alloy steel used in these slab clamps delivers exceptional tensile strength—often exceeding 1200 MPa—ensuring robust performance under heavy loads. This material enhances resistance to wear, fatigue, and corrosion, indispensable in harsh industrial environments. Precision manufacturing techniques and strict quality control certify that clamps meet international safety standards such as ISO 12100 and EN 13155, reinforcing confidence among operators.

Structurally, these clamps incorporate reinforced gripping jaws lined with abrasion-resistant inserts, enabling secure handling of slabs without surface damage. The ergonomic design of the clamp arms optimizes load distribution, reducing stress concentrations and extending equipment lifespan.

These slab clamps typically accommodate lifting capacities ranging from 2 to 50 metric tons, catering to both light and ultra-heavy plate handling scenarios. Selection should consider the slab’s thickness and weight to ensure optimal safety margins—usually a minimum safety factor of 5 is recommended.

Drive mechanisms vary between manual, hydraulic, and pneumatic systems. Manual clamps offer cost-effective solutions for moderate loads up to 10 tons, ideal for smaller-scale operations. Hydraulic drive options, predominant in medium to heavy-duty applications, provide controlled gripping forces adjustable via pressure regulation. Pneumatic drives are advantageous in environments where fast, repetitive lifting cycles demand high responsiveness and minimal operator fatigue.

| Drive Mechanism | Typical Load Capacity (tons) | Ideal Application | Key Benefit |

|---|---|---|---|

| Manual | 2 - 10 | Small workshops, Maintenance | Cost-effective & simple control |

| Hydraulic | 5 - 50 | Ports, Metalworks, Heavy Industry | Adjustable force & reliable grip |

| Pneumatic | 3 - 20 | High-cycle Manufacturing Lines | Rapid response & reduced fatigue |

Cutting-edge slab clamps prioritize operator safety through multiple integrated devices. Anti-slip rubber pads and serrated jaws minimize slab slippage risks during lifting and transport. Overload protection valves prevent excessive clamping pressure, safeguarding both the material and equipment. Many models include locking mechanisms that secure the clamp to the slab during transit, eliminating accidental releases.

Regular maintenance accessibility is designed into clamp architecture, reducing downtime and enabling swift parts replacement. Compliance with safety regulations like OSHA and ANSI standards further underscores these clamps’ suitability for industrial environments.

In a notable metallurgical plant in Germany, upgrading to hydraulic high-strength alloy steel slab clamps increased slab handling throughput by 25%, while operating incident reports related to slab displacement dropped by 40% within the first six months. Operators praised the ergonomic design reducing manual strain and the adjustable gripping force optimizing slab handling without damage.

Similarly, a major port facility in the UAE integrated pneumatic slab clamps to streamline container loading processes. Fast gripping cycles and enhanced reliability contributed to a 15% reduction in vessel loading times, proving instrumental in meeting tight shipping schedules without compromising safety.

To select the ideal slab clamp, companies should carefully evaluate the following factors:

Strategic investments in premium alloy materials and safety systems reduce long-term operational costs by minimizing accident risks and extending service life.

Our range of high-strength alloy steel slab clamps is engineered to meet precise specifications and diverse industrial demands. Equipped with the latest safety features and customizable drive options, these clamps promise to enhance your material handling safety and productivity.

Discover How Our Slab Clamps Can Revolutionize Your Material Handling Today