In the steel and metallurgical industries, handling heavy steel plates efficiently not only impacts productivity but also influences workplace safety. Yet, many procurement specialists struggle when it comes to choosing industrial lifting clamps that fit different steel plate sizes and operational environments. The challenge mostly boils down to balancing strength, adaptability, and ease of use—without overspending on overengineered tools.

This guide delves into the technical features and practical applications of Dalian Taiding Heavy Industry’s custom-sized steel plate lifting clamps. With a proven transmission mechanism and robust structural design, these clamps stand out for enhancing safety and efficiency in demanding scenarios like continuous casting workshops and hot rolling mills.

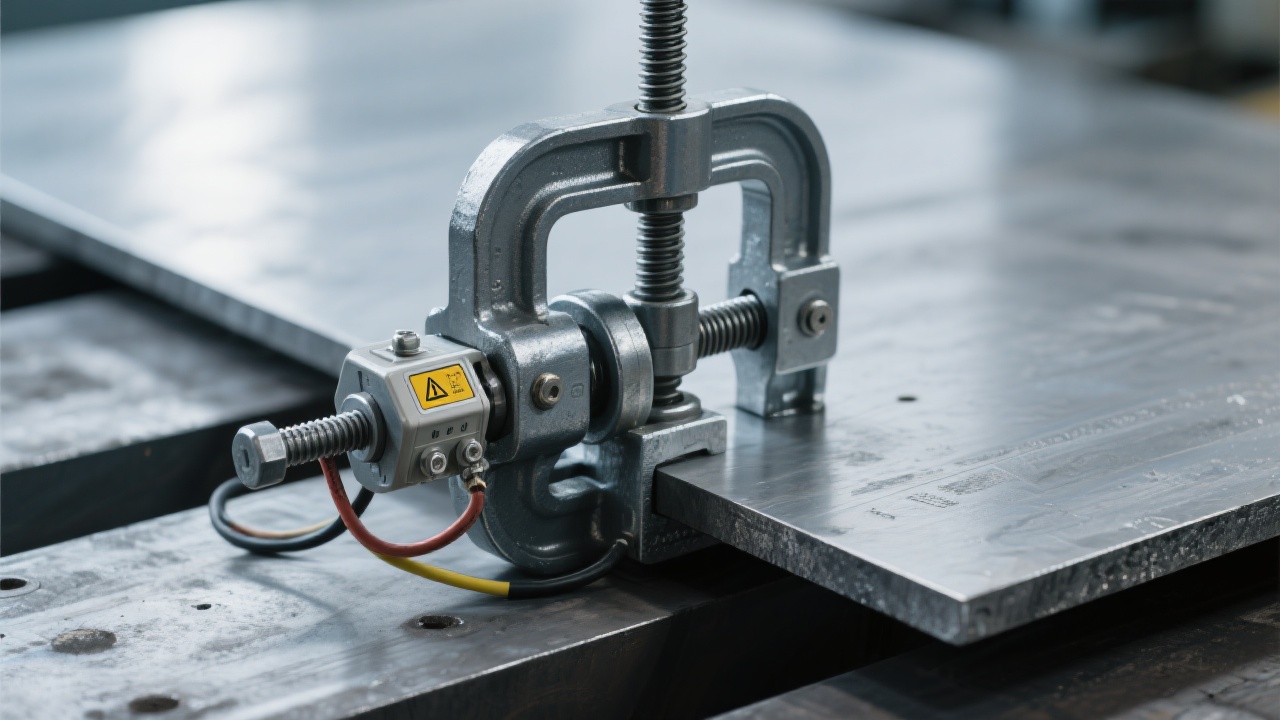

The heart of an effective steel plate clamp lies in its transmission mechanism. Unlike conventional designs, Taiding’s clamps incorporate a gear-driven system that ensures equal load distribution across all gripping points. This precision mechanism minimizes slippage risks, which are otherwise a common cause of accidents in steel mills.

From a structural perspective, the clamps utilize high-tensile alloy steel with surface treatments resistant to corrosion and abrasion. Load tests indicate a safety factor exceeding 1.5 times the rated load capacity, providing a dependable margin in harsh industrial conditions.

In fast-paced logistics scenarios, downtime from clamp adjustments can negatively affect throughput. That’s why Taiding’s clamps feature intuitive quick-adjust settings, allowing operators to tune grip widths within seconds, accommodating steel plate thicknesses ranging from 6 mm to over 120 mm effortlessly.

Furthermore, built-in safety locks and fail-safe mechanisms reduce operator fatigue and human error. Integrating visual load indicators also assists maintenance teams in scheduling timely inspections, thus lowering unexpected failures and associated costs.

| Clamp Model | Steel Plate Thickness Range (mm) | Safe Working Load (tons) | Recommended Application |

|---|---|---|---|

| TD-SC6 | 6 - 20 | 3 | Warehouse stacking, light steel fabrication |

| TD-SC40 | 20 - 65 | 10 | Hot rolling mills, intermediate plate handling |

| TD-SC120 | 65 - 120+ | 25 | Continuous casting workshops, heavy industrial transfer |

It’s evident that one size never fits all in steel plate handling. For instance, the TD-SC120 clamp, with a 25-ton safe working load, has been pivotal in a recent deployment at a Chinese continuous casting plant, where larger slabs—up to 100 mm thick—required secure, rapid transfers. The operational data showed a 22% decrease in handling time and a notable reduction in workplace incidents, highlighting the clamp’s practical value.

While purchasing high-quality lifting clamps might seem a larger initial investment, the longer lifecycle and lower downtime translate into significant cost savings. According to a steel logistics study, maintenance expenses can drop by up to 18%, and throughput can improve approximately 15% when using tailored clamps versus generic models.

Predictive maintenance features of Taiding’s clamps further aid enterprises in scheduling repairs before failures occur, aligning asset management with Industry 4.0 smart factory principles, which many steel companies are increasingly adopting.

Ready to upgrade your steel plate handling tools with reliable, custom lifting clamps? Discover tailored solutions designed to boost your operational safety and efficiency today!

Your industry might have distinctive steel handling challenges—what’s your current pain point? Share your application scenarios with us, and we’ll provide you with three optimized steel plate clamp cases from similar industries to inspire your next step.