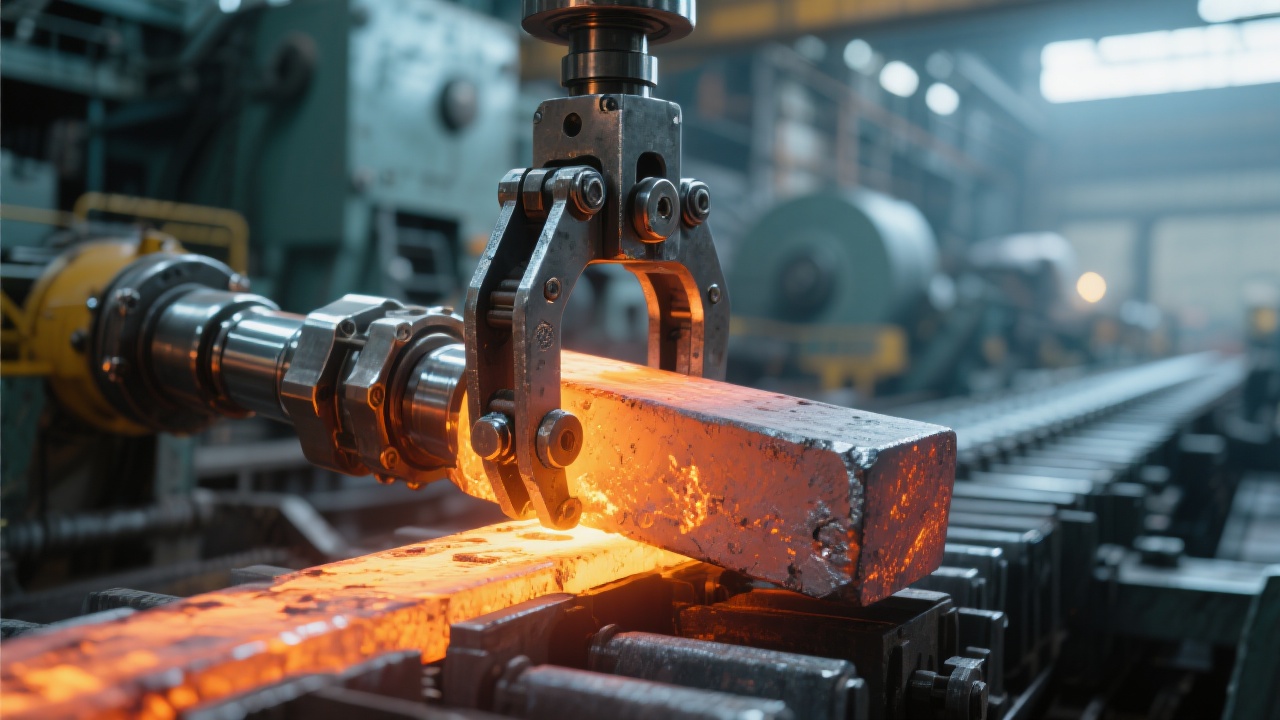

In the world of steel production and logistics, the efficiency and safety of slab handling are of paramount importance. Dalian Tiding Heavy Industry Co., Ltd. has introduced a low-maintenance mechanical slab tong that leverages advanced hydraulic drive technology to revolutionize slab handling operations. This article delves into how this innovative product enhances efficiency and safety in the steel industry, offering practical solutions for steel producers and international traders.

Slab tongs play a central role in steel production and logistics, facilitating the movement of heavy slabs from one stage of the process to another. The hydraulic drive technology employed in Dalian Tiding's slab tongs brings significant improvements in operation precision and safety. Unlike traditional tongs, the hydraulic system allows for more accurate control, ensuring that slabs are lifted and transported with minimal risk of slippage or damage.

The slab tongs are crafted from high-strength alloy steel, a material known for its exceptional durability and resistance to wear. In the harsh environment of high temperatures and heavy loads, this material excels. Tests have shown that the tongs can withstand temperatures up to [X] degrees Celsius and carry loads of up to [X] tons without significant wear and tear. This durability not only reduces maintenance costs but also extends the service life of the tongs, providing long-term value to steel producers.

To illustrate the effectiveness of Dalian Tiding's slab tongs, let's look at a real-world example. [Company Name], a leading steel producer, implemented these tongs in their production line. Before the adoption, they faced challenges such as frequent breakdowns of traditional tongs and low efficiency in slab handling. After using the new tongs, they witnessed a [X]% increase in slab handling efficiency and a [X]% reduction in maintenance costs within the first six months. Moreover, the improved safety features led to a significant decrease in workplace accidents.

| Metrics | Before Adoption | After Adoption |

|---|---|---|

| Handling Efficiency | [X] slabs per hour | [X] slabs per hour |

| Maintenance Costs | $[X] per month | $[X] per month |

| Accident Rate | [X]% | [X]% |

In steel production and logistics, there are several common challenges in slab handling, such as difficulty in handling hot slabs, high risk of slab damage, and low efficiency. Dalian Tiding's slab tongs address these issues effectively. The hydraulic drive system allows for precise control even when handling hot slabs, reducing the risk of damage. The high-strength alloy steel construction ensures durability, making the tongs suitable for long-term use in demanding environments.

When compared with similar products in the market, Dalian Tiding's slab tongs stand out. Competitor products may lack the advanced hydraulic drive technology or the high-quality alloy steel construction. As a result, they often suffer from lower precision, shorter service life, and higher maintenance costs. In contrast, Dalian Tiding's tongs offer a more reliable and cost-effective solution, providing a competitive edge to steel producers.

We invite you to share your thoughts and questions about Dalian Tiding's slab tongs. Have you faced any challenges in slab handling? Do you think these tongs could be a suitable solution for your business? Leave your comments below, and our experts will be happy to answer them.

Dalian Tiding's hydraulic drive slab tongs are a game-changer in the steel industry. With their advanced technology, high durability, and proven effectiveness, they offer a practical solution for improving slab handling efficiency and safety. Whether you are a steel producer looking to optimize your production process or an international trader seeking high-quality steel handling equipment, these tongs are worth considering. To learn more about our products and how they can benefit your business, click here.