The aluminum processing industry is currently facing numerous challenges. Global demand for aluminum products is on the rise, but at the same time, manufacturers are under pressure to improve production efficiency, reduce costs, and enhance safety. Inefficient handling and transportation of aluminum ingots can lead to production bottlenecks, increased labor costs, and potential safety hazards. According to industry statistics, approximately 30% of production delays in the aluminum processing industry are related to inefficient ingot handling equipment. This highlights the urgent need for high - performance, reliable equipment.

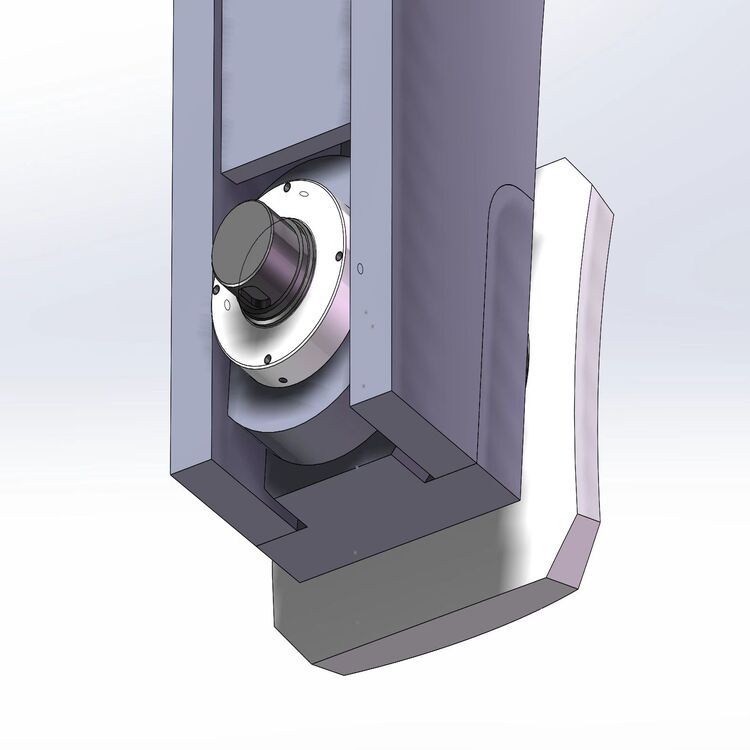

Hydraulic aluminum ingot clamps are specifically designed for the handling and transportation of aluminum ingots. These clamps are made of high - strength alloy steel, which provides excellent durability and resistance to wear. For example, the tensile strength of the material used in our clamps can reach up to 1000 MPa, ensuring long - term reliable operation even under heavy loads.

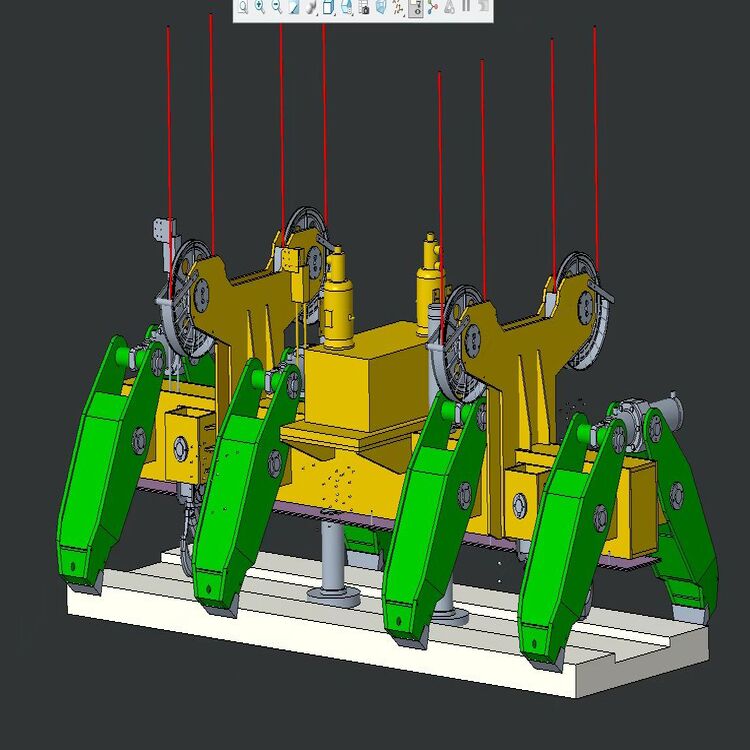

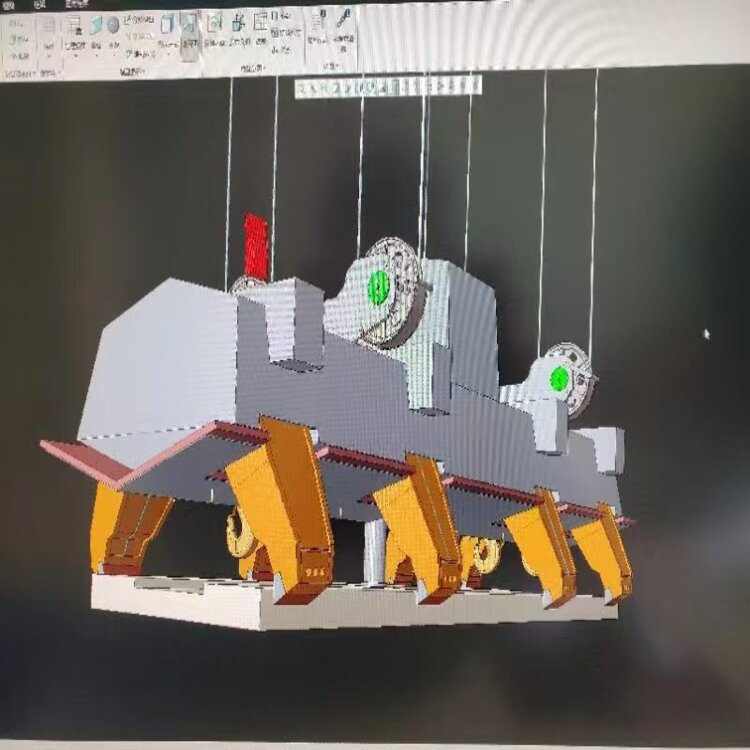

In terms of structure, the innovative clamping mechanism is the key feature of these clamps. The hydraulic system allows for precise control of the clamping force, ensuring that the aluminum ingots are firmly held during handling and transportation. The clamping force can be adjusted according to the size and weight of the ingots, with a maximum clamping force of up to 50 tons.

Functionally, these clamps are equipped with advanced sensors and control systems. The sensors can detect the position and status of the ingots in real - time, and the control system can automatically adjust the clamping force and operation parameters, improving the overall efficiency and accuracy of the handling process.

Safety is a top priority in the aluminum processing industry. Hydraulic aluminum ingot clamps significantly reduce the risk of accidents during transportation. By firmly holding the ingots, the risk of dropping and collisions is minimized. In fact, in companies that have adopted our clamps, the accident rate related to ingot transportation has been reduced by more than 50%.

In terms of efficiency, these clamps can greatly increase the handling speed. Traditional manual handling methods can only process about 10 - 15 ingots per hour, while our hydraulic clamps can handle up to 50 - 60 ingots per hour, effectively improving the overall production efficiency.

Hydraulic aluminum ingot clamps are widely applicable in various industrial fields. In aluminum smelters, they are used for the transfer of newly produced ingots from the production line to storage areas or transportation vehicles. In aluminum processing plants, these clamps are used for the loading and unloading of ingots during the production process. They are also suitable for use in logistics and warehousing operations, facilitating the efficient storage and distribution of aluminum ingots.

The application of these clamps in different industries has brought significant benefits. For example, in an aluminum smelter in Europe, after using our clamps, the overall production efficiency has increased by 30%, and the labor cost has been reduced by 20%.

One of our customers, an aluminum processing company in Asia, was facing problems with slow production speed and high accident rates due to the use of outdated handling equipment. After adopting our hydraulic aluminum ingot clamps, they saw a remarkable improvement. The production efficiency increased from 80 tons per day to 120 tons per day, and the number of accidents related to ingot handling dropped to almost zero. The company's manager said, “These clamps have revolutionized our production process, allowing us to achieve higher productivity and better safety.”

Compared with similar products in the market, our hydraulic aluminum ingot clamps have several unique advantages. Firstly, our products use high - quality materials and advanced manufacturing processes, ensuring better durability and reliability. Secondly, the innovative clamping mechanism provides more precise control of the clamping force, which is superior to many traditional mechanical clamps. Thirdly, our clamps are equipped with intelligent control systems, which can adapt to different working conditions and improve the overall efficiency.

If you are looking for a reliable solution to improve the efficiency and safety of your aluminum processing operations, our hydraulic aluminum ingot clamps are the ideal choice. They can help you upgrade your production processes, reduce costs, and enhance your competitiveness in the global market. Click here to learn more about our products and start your journey towards a more efficient and safer aluminum processing operation.