The global aluminum industry is undergoing a significant transformation driven by the need for safer, more efficient, and sustainable production methods. Among the key innovations fueling this shift is the hydraulic aluminum ingot clamp, a critical tool that enhances both safety and productivity in aluminum handling and transportation.

With its advanced clamping mechanism and robust construction, the hydraulic aluminum ingot clamp has become an essential component in modern aluminum processing plants. This article explores the technical features, material advantages, and real-world applications of this innovative equipment, highlighting its role in driving industrial efficiency and meeting international safety standards.

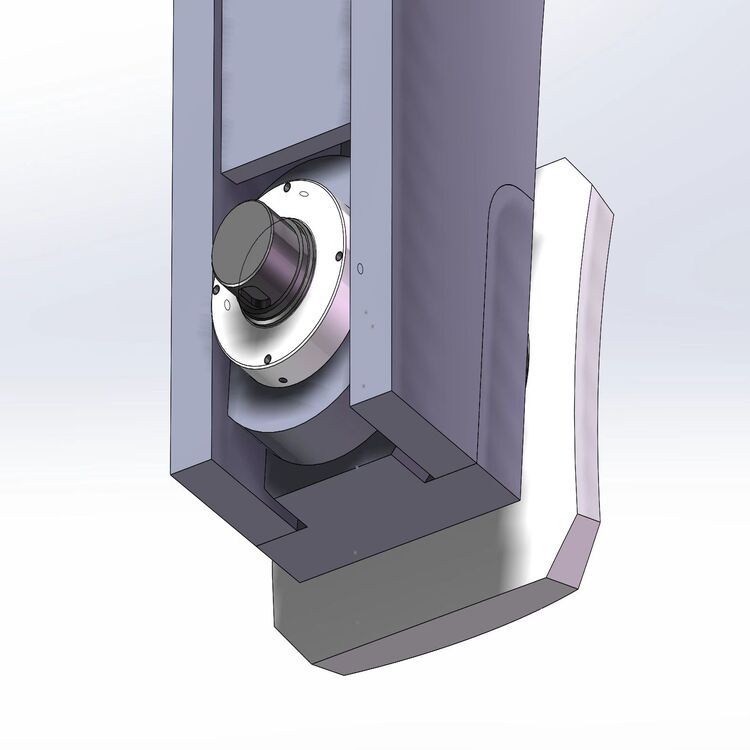

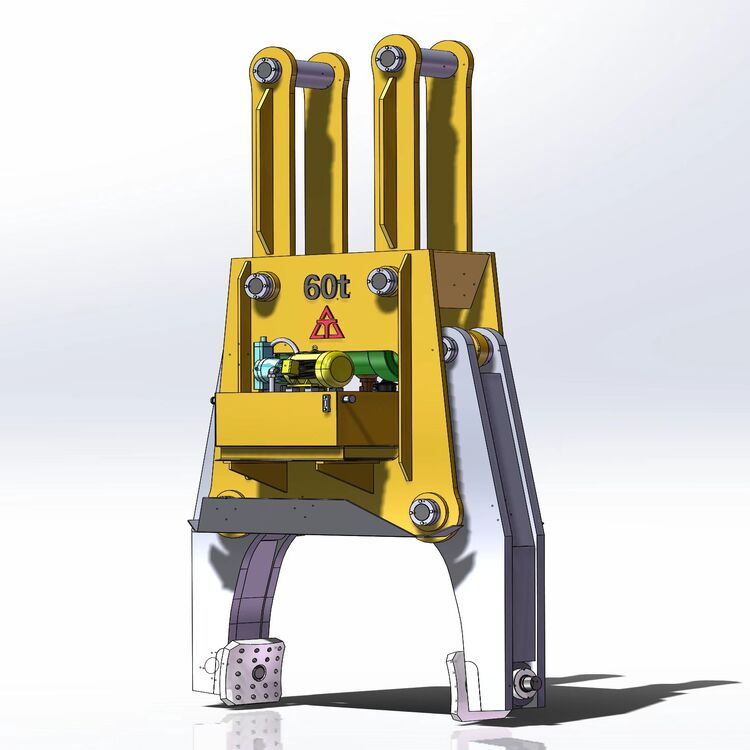

The core of the hydraulic aluminum ingot clamp lies in its hydraulic clamping system, which provides precise control over the gripping force applied to aluminum ingots. Unlike traditional mechanical clamps, this system ensures consistent pressure distribution, reducing the risk of damage during transport and storage.

Equipped with high-strength alloy steel components, the clamp can withstand heavy loads—up to 50 tons—without compromising structural integrity. The use of precision-engineered hydraulic cylinders allows for smooth and reliable operation, even under extreme conditions.

As global trade expands, adherence to strict safety regulations becomes a non-negotiable requirement for manufacturers. The hydraulic aluminum ingot clamp is designed to meet international safety standards such as ISO 9001 and OSHA, ensuring that it can be used across multiple markets without compromise.

Its reinforced structure and durable materials make it suitable for use in hazardous environments, while the integrated safety locks prevent accidental release during transit. These features not only protect the product but also reduce liability risks for operators.

The versatility of the hydraulic aluminum ingot clamp makes it a valuable asset in various industries, including:

By integrating this clamp into existing workflows, companies have reported up to a 30% increase in operational efficiency and a 40% reduction in material damage. Its ability to handle large volumes quickly and safely streamlines production lines and reduces downtime.

A major aluminum processing plant in Southeast Asia implemented the hydraulic aluminum ingot clamp across its production and logistics operations. Within six months, the facility saw a marked improvement in safety metrics and throughput.

According to internal reports:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Material Damage Rate | 12% | 7% |

| Transportation Time per Batch | 4 hours | 3 hours |

| Operator Fatigue Index | High | Moderate |

This case study underscores the practical benefits of adopting the hydraulic aluminum ingot clamp, proving its value in real-world settings.

Compared to conventional clamping solutions, the hydraulic aluminum ingot clamp offers distinct advantages:

These features position the hydraulic aluminum ingot clamp as a preferred choice for forward-thinking manufacturers aiming to stay competitive in the global market.

The hydraulic aluminum ingot clamp represents a pivotal advancement in the aluminum processing industry. By combining cutting-edge technology, superior materials, and proven performance, it delivers unmatched safety and efficiency. As the demand for high-quality aluminum products continues to rise, investing in this innovative solution will help businesses future-proof their operations and gain a strategic advantage.

Ready to upgrade your aluminum handling systems? Discover how our hydraulic aluminum ingot clamp can transform your workflow today.

Explore Our Products Now