As the global aluminum processing industry continues to evolve, manufacturers are facing increasing demands for efficiency, safety, and reliability in material handling. Traditional methods of transporting and clamping aluminum ingots often lead to risks such as deformation, damage, or even accidents during logistics. This is where the innovative hydraulic aluminum ingot clamp technology from Dalian Tideng Heavy Industry steps in, offering a solution that enhances productivity while ensuring operational safety.

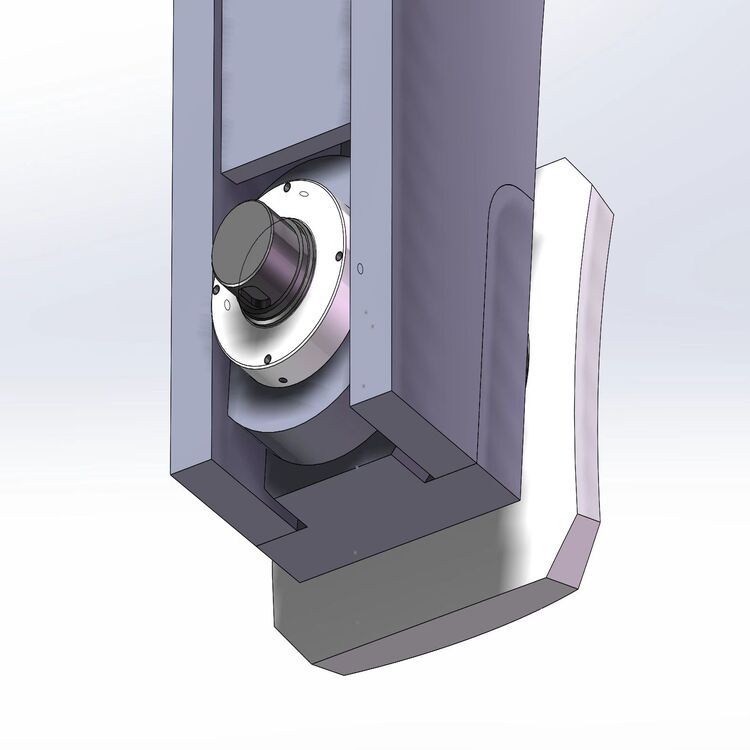

The hydraulic aluminum ingot clamp is engineered with high-strength materials, providing exceptional load-bearing capacity. It can handle ingots weighing up to 4,000 kg without compromising stability. The advanced clamping mechanism ensures a secure grip on the ingot surface, significantly reducing the risk of slippage or damage during transport.

Compared to traditional mechanical clamps, this system offers greater precision and control. Its hydraulic design allows for smooth operation and easy adjustment, making it suitable for various production environments. Additionally, the compact structure of the clamp makes it ideal for integration into existing production lines without requiring major modifications.

| Feature | Specification |

|---|---|

| Load Capacity | Up to 4,000 kg |

| Material | High-strength steel alloy |

| Clamping Mechanism | Hydraulic-driven, adjustable pressure |

| Operating Pressure | 15–25 MPa |

The hydraulic aluminum ingot clamp is designed for use in a wide range of industries, including but not limited to aluminum smelting, casting, and transportation. It is particularly well-suited for facilities that require frequent movement of large aluminum ingots between production stages or shipping docks.

By integrating this clamp into their workflow, manufacturers can optimize production efficiency, reduce downtime, and improve overall operational safety. This not only meets international standards for product quality and safety but also positions companies to better compete in the global market.

Several global clients have already adopted the hydraulic aluminum ingot clamp from Dalian Tideng Heavy Industry and reported significant improvements in their operations. One major aluminum producer in Southeast Asia saw a 30% reduction in transport-related incidents after implementing the system. Another company in Europe noted a 25% increase in production output due to faster and more reliable material handling.

These success stories highlight the practical benefits of the clamp, proving its value in real-world applications across different regions and production scales.

Unlike conventional clamping systems, Dalian Tideng’s hydraulic aluminum ingot clamp offers superior durability, precise control, and ease of integration. With a focus on innovation and user-centric design, the product is built to meet the evolving needs of modern manufacturing. Its compliance with international safety standards further reinforces its reliability and performance in global markets.

For businesses looking to enhance their production capabilities and ensure safer, more efficient material handling, the hydraulic aluminum ingot clamp is an essential investment. Discover how this cutting-edge technology can transform your operations today.