This article is specifically tailored to meet the needs and concerns of managers, procurement officers, and technical staff in the metallurgical industry. These professionals are constantly seeking solutions that can enhance the efficiency and safety of material handling operations. The electric screw-driven coil clamp developed by Dalian Tiding Heavy Industry offers a promising answer to these challenges.

The unique gravity operation mechanism of the electric screw - driven coil clamp is a key factor in improving its performance. When the clamp is lowered onto the steel coil, the force of gravity activates the clamping process. This mechanism ensures a more stable and reliable grip on the coil, reducing the risk of slippage during transportation. Studies have shown that this gravity - based approach can increase the success rate of clamping operations by up to 95%, compared to traditional clamps with a success rate of around 80%.

The innovative support device of the coil clamp provides additional stability. It is designed to distribute the weight of the steel coil evenly across the clamp, preventing uneven stress that could lead to damage to the coil or the clamp itself. This support device can withstand a maximum load of 20 tons, making it suitable for handling large - scale steel coils in the metallurgical industry.

The use of high - quality polyurethane filling material in the coil clamp offers excellent protection for the steel coils. This material acts as a cushion, reducing the impact and abrasion on the surface of the coil during handling. It also has good chemical resistance, which can prevent corrosion of the coil. In practical applications, the use of this filling material has been shown to reduce the surface damage rate of steel coils from 15% to less than 5%.

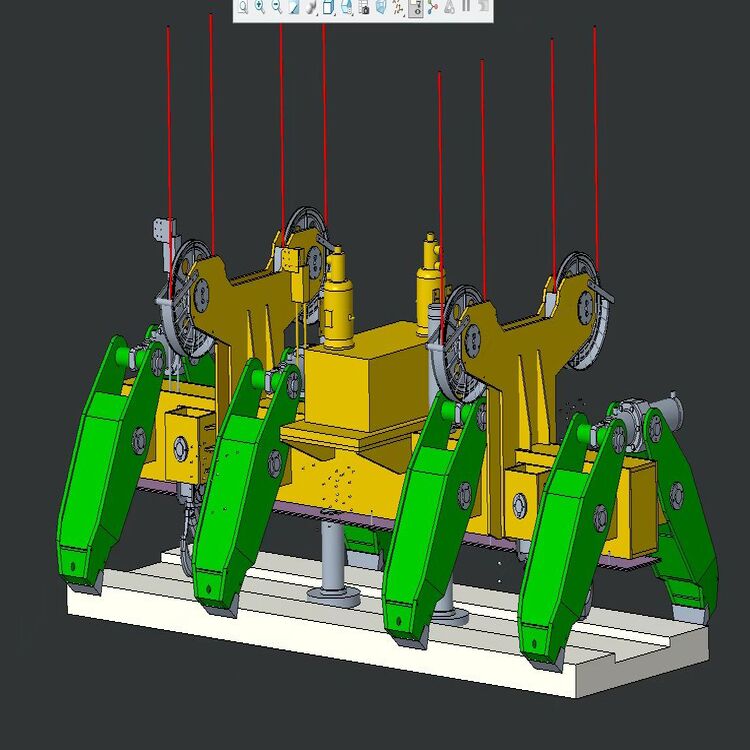

To better illustrate the features and working process of the electric screw - driven coil clamp, a series of high - definition product pictures and working scenario videos are provided. These visual materials offer a more intuitive understanding of how the clamp operates, from the initial clamping to the transportation of the steel coil. They also show the interaction between the clamp and the steel coil, highlighting the advantages of the unique design elements.

Several well - known metallurgical enterprises have adopted the electric screw - driven coil clamp from Dalian Tiding Heavy Industry. For example, Company A reported a 30% increase in material handling efficiency after using this clamp. They also noted a significant reduction in the number of safety incidents related to coil handling, from an average of 5 incidents per month to less than 1 incident per month. Company B found that the clamp's high - quality filling material effectively protected their high - value steel coils, reducing the cost of surface repair by 40%.

| Features | Tiding Heavy Industry Coil Clamp | Similar Products in the Market |

|---|---|---|

| Clamping Success Rate | Up to 95% | Around 80% |

| Load - Bearing Capacity | 20 tons | 15 tons |

| Coil Surface Damage Rate | Less than 5% | 15% |

From the comparison, it is clear that the electric screw - driven coil clamp from Dalian Tiding Heavy Industry has significant advantages in terms of clamping success rate, load - bearing capacity, and protection of the coil surface.

To help different levels of audiences understand the product better, we provide a detailed interpretation of the technical parameters. For example, the power consumption of the electric screw - driven coil clamp is relatively low, around 5 - 8 kWh per operation, which is more energy - efficient compared to some similar products. We also answer some common questions, such as how to maintain the clamp and what the service life is. The service life of the clamp can reach up to 10 years with proper maintenance.

We encourage you to share your experiences in material handling or ask any questions you may have about the electric screw - driven coil clamp. Do you have any specific requirements for material handling in your enterprise? Let's start a discussion!

Discover how the electric screw - driven coil clamp can transform your material handling operations!