In continuous casting operations—where temperatures exceed 1,400°C and throughput demands are relentless—steel plate handling isn’t just a logistical task—it’s a safety-critical process. Yet many facilities still rely on generic lifting solutions that lead to inefficiencies, equipment wear, and even workplace incidents.

According to our field data from over 30 global clients across steel mills, hot rolling plants, and port terminals, traditional clamps cause:

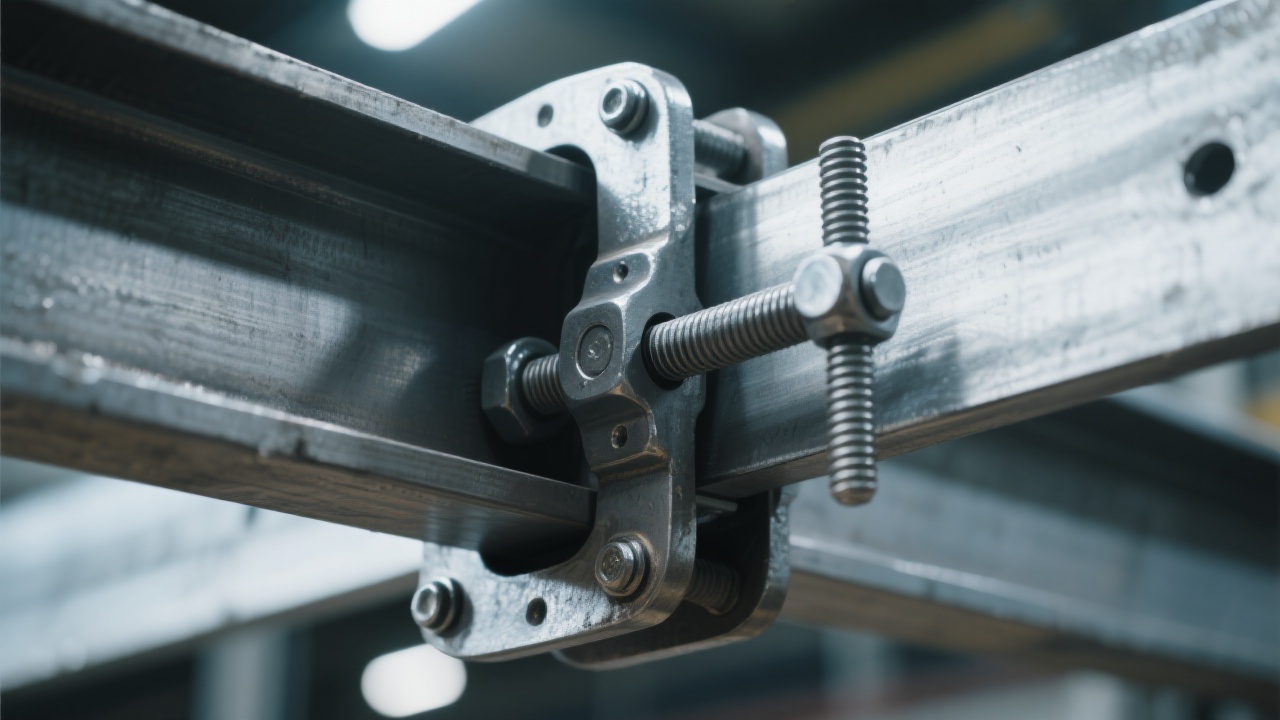

Dalian Tiding Heavy Industry’s custom steel plate handling clamps solve these issues through three core innovations:

| Feature | Benefit |

|---|---|

| Dual-Stage Mechanical Transmission | Eliminates slippage under heavy load (up to 50 tons) — critical for hot slab transfer |

| Forged Alloy Frame (EN10027-2 Grade 42CrMo4) | Withstands thermal expansion cycles without deformation — tested up to 800°C |

| Quick-Adjustment Jaw Mechanism (107+ Sizes) | Switch between 5mm–150mm thickness plates in under 90 seconds — no tools required |

These aren’t theoretical specs—they’re proven in real environments:

Case Study: Port of Santos, Brazil – Hot Rolled Coil Yard

Before using Dalian Tiding’s clamps, the facility experienced an average of 4.3 equipment failures per month during high-volume shifts. After switching to their modular system, failure rates dropped to 0.7/month—a 84% reduction—and crane cycle times improved by 27%. Operators reported “more confidence in each lift,” especially when handling 30mm-thick slabs at 750°C.

Whether it’s the extreme heat of a continuous caster, the precision needed in a hot rolling mill, or the variability of dockside logistics, this clamp adapts:

With over 30 models and 107+ size configurations, you can choose the exact fit for your operation—not compromise.

Pro Tip: Don’t just buy a clamp—buy a solution. The right one will reduce maintenance time by 30%, improve operator safety, and extend equipment life. That’s not marketing—it’s what we’ve seen in 30+ countries.

If you're facing bottlenecks in steel plate handling—whether in casting, rolling, or storage—ask yourself: Is my current setup optimized for performance, or just surviving?

Ready to make every lift more precise, safer, and faster?

Get Your Free Equipment Compatibility Assessment →

Have a unique challenge in your steel plant? Let us know your exact scenario—we’ll share 3 industry-specific case studies tailored to your needs.