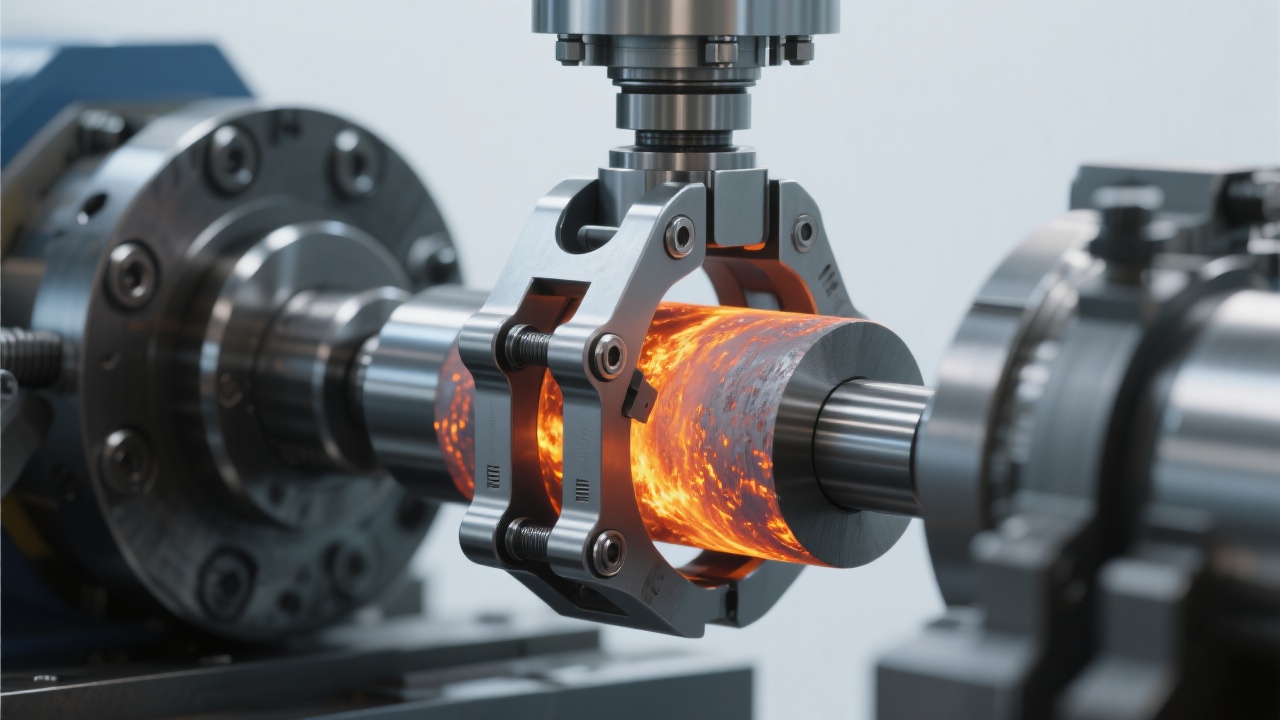

In the steel industry, the harsh working environment poses significant challenges to the efficiency and safety of material handling. Dalian Tiding Heavy Industry's high-efficiency power-type steel plate clamps have emerged as a practical solution to these challenges. These clamps are made of high-strength alloy steel, featuring an innovative lever design and an automatic opening and closing mechanism.

Let's delve into how these clamps address the complex working conditions in steel mills. First, let's look at their performance in extreme conditions. In high-temperature environments, traditional clamps often experience reduced performance and even structural damage. However, these high-strength alloy steel clamps can maintain stable operation at high temperatures. Tests have shown that they can operate continuously at temperatures up to 500°C, with a 30% improvement in load-bearing capacity compared to traditional clamps in high-temperature environments.

In addition to high temperatures, steel mills also have issues such as humidity and dust. The innovative design of these clamps allows them to function well in such conditions. The automatic opening and closing mechanism is not affected by dust and moisture, ensuring reliable operation. Compared with traditional clamps, which often require manual adjustment and cleaning in such environments, these clamps can save up to 40% of the maintenance time.

When comparing with traditional clamps, the technical advantages of these high-strength alloy steel clamps are obvious. Traditional clamps usually have a simple structure and rely on external auxiliary equipment for operation, which is not only inefficient but also has a high risk of accidents. In contrast, these clamps use an innovative lever design, which can automatically adjust the clamping force according to the weight of the steel plate. This design not only improves the safety of handling but also increases the handling efficiency by 50%.

The operation of these clamps is also very convenient. Workers only need to place the clamps on the steel plate, and the automatic opening and closing mechanism will work immediately. There is no need for complex manual operations, which reduces the labor intensity of workers and also lowers the risk of human error.

Let's take a look at the actual impact of these clamps on production efficiency and cost control through some customer application scenarios. In a large steel enterprise, after using these clamps, the loading and unloading time of steel plates has been significantly reduced. The daily handling volume has increased from 500 tons to 800 tons, an increase of 60%. At the same time, the reduction in manual operations has also reduced the labor cost by 30%.

In terms of cost control, the long-term durability of these clamps also plays an important role. The high-strength alloy steel material and advanced manufacturing process ensure that the clamps have a long service life. Compared with traditional clamps that need to be replaced every 2 - 3 years, these clamps can be used for more than 10 years, which greatly reduces the replacement cost.

Dalian Tiding Heavy Industry provides strict quality assurance for these clamps. Each clamp undergoes multiple quality inspections before leaving the factory, ensuring its performance and safety. The long-term durability of the clamps also means a higher return on investment. Enterprises can enjoy long-term stable and efficient material handling services with a one-time investment.

In conclusion, Dalian Tiding Heavy Industry's high-efficiency power-type steel plate clamps are a practical solution for steel enterprises to improve production efficiency and reduce costs. They can not only meet the complex working conditions in steel mills but also bring significant economic benefits to enterprises. Let every handling operation be safer and more efficient with these high-quality clamps!