The global aluminum processing industry is currently facing a series of challenges, such as intense market competition, rising raw material costs, and increasing environmental protection requirements. These challenges have forced enterprises in the industry to seek upgrading and transformation. In this context, the importance of hydraulic aluminum ingot clamps has become increasingly prominent. Dalian Titanium Ding Heavy Industry's hydraulic aluminum ingot clamps are playing a crucial role in promoting the upgrading of the aluminum processing industry.

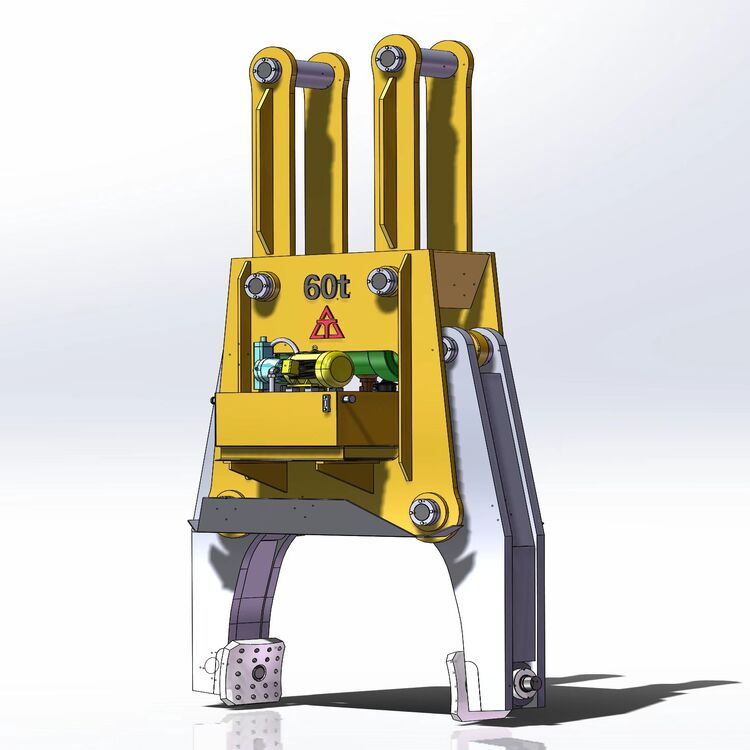

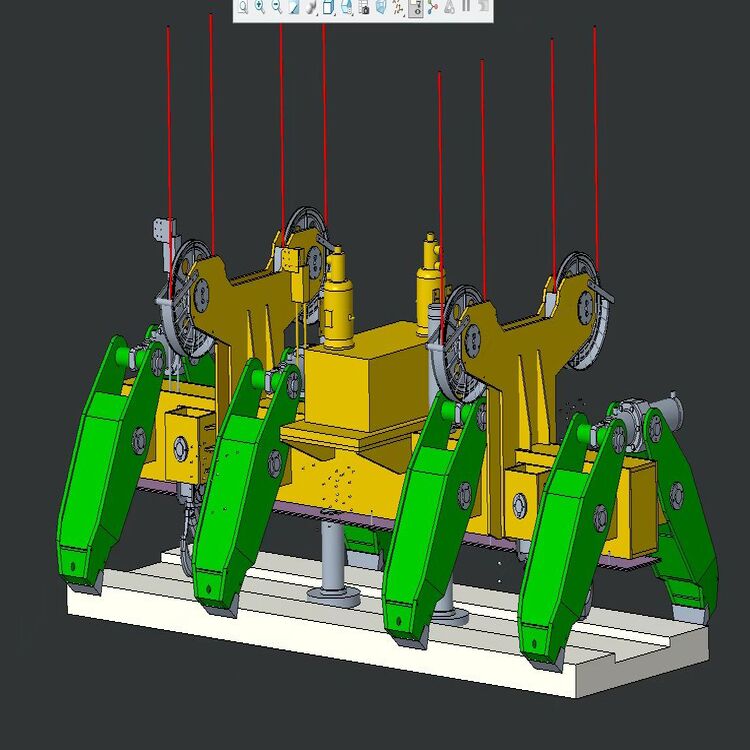

Dalian Titanium Ding Heavy Industry's hydraulic aluminum ingot clamps are made of high - strength materials, which can withstand a large amount of pressure. For example, these clamps can bear a maximum load of up to 5 tons, ensuring the safe and stable transportation of aluminum ingots. Its innovative clamping mechanism is another highlight. The unique design can firmly grip the aluminum ingot, reducing the risk of damage during transportation. The clamping force can reach up to 8000 N, which effectively prevents the aluminum ingot from slipping or falling.

These hydraulic aluminum ingot clamps are suitable for multiple industrial fields, including the aluminum smelting industry, metal processing plants, and logistics and transportation companies. In the aluminum smelting industry, they can be used to quickly transfer aluminum ingots from the production line to the storage area, improving production efficiency by about 30%. In metal processing plants, the clamps help to precisely position the aluminum ingots during the processing, enhancing the quality of the finished products. In logistics and transportation, they ensure the safety of aluminum ingot transportation, reducing the loss rate to less than 1%.

Many customers have achieved excellent results after using Dalian Titanium Ding Heavy Industry's hydraulic aluminum ingot clamps. For example, a large - scale aluminum smelting company in the United States reported that after replacing the old - fashioned clamps with these new ones, their production cost was reduced by 20% due to the lower damage rate and higher efficiency. Another metal processing factory in Germany found that the product qualification rate increased by 15% after using these clamps, thanks to the more precise clamping and positioning.

Compared with other similar products on the market, Dalian Titanium Ding Heavy Industry's hydraulic aluminum ingot clamps have obvious advantages. In terms of material strength, most of its competitors' products can only bear a load of about 3 tons, while these clamps can reach 5 tons. In terms of clamping force, the competitors' average clamping force is around 6000 N, which is significantly lower than the 8000 N of Dalian Titanium Ding Heavy Industry's products. Moreover, the innovative design of these clamps is more user - friendly and easier to operate, which can save a lot of labor costs for enterprises.

Discover the superior performance of Dalian Titanium Ding Heavy Industry's hydraulic aluminum ingot clamps. Visit our website www.example.com to learn more about our products and how they can benefit your business!