In the high - stakes world of steel transportation, efficiency and safety are non - negotiable. Enter Dalian Tiding Heavy Industry's Motorized Slab Clamp, a game - changing hydraulic grabbing device specifically engineered for the heavy - duty casting and transportation needs of the global steel industry.

With the steel market constantly evolving, the demand for equipment that can handle large - scale operations with precision has skyrocketed. Dalian Tiding recognized this need and developed a product that stands out in a crowded marketplace.

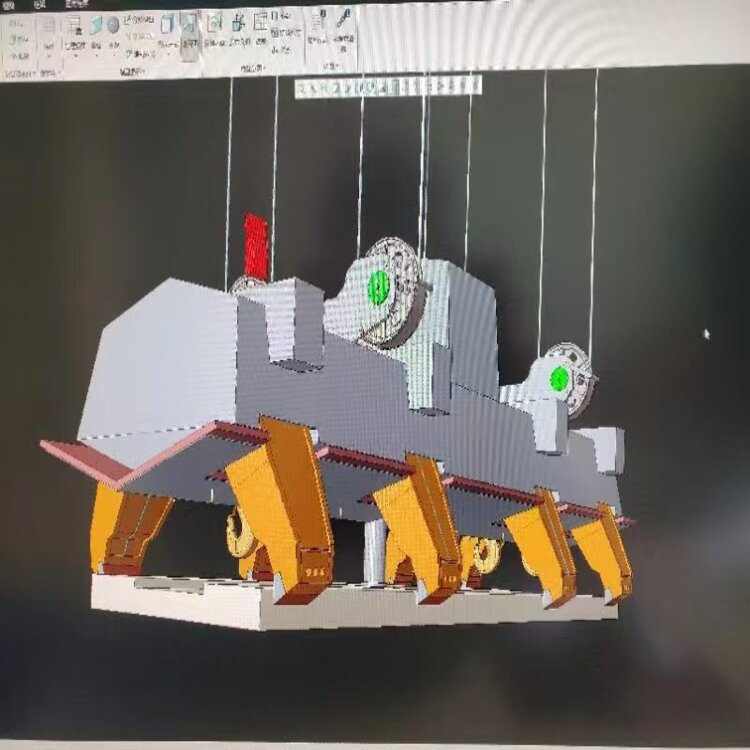

The cornerstone of this remarkable device is its state - of - the - art hydraulic system. This system is designed to provide a consistent and powerful grip, capable of handling steel ingots ranging from 8 tons to 550 tons. With a high - pressure output of up to 3000 psi, it ensures a secure hold during transportation, reducing the risk of accidents and product damage.

The clamp's compact design is another significant advantage. Measuring just 3 meters in length and 1.5 meters in width, it can easily maneuver in tight spaces, such as narrow aisles in steel mills. This not only improves operational flexibility but also enhances overall productivity by reducing the time required for loading and unloading.

Safety is at the forefront of the design. The clamp is equipped with multiple safety features, including overload protection and emergency stop buttons. These features, combined with its efficient operation, result in a significant reduction in downtime and an increase in the overall throughput of steel transportation operations. In fact, steel mills using this clamp have reported a 30% increase in daily transportation volume.

In various steel mills around the world, the Motorized Slab Clamp has proven its worth. For example, in a large - scale rolling mill in Germany, the clamp has been used to transport steel slabs from the casting area to the rolling machines. Since its installation, the mill has seen a 25% reduction in transportation - related accidents and a 20% improvement in production efficiency.

In a reheating furnace workshop in Japan, the compact design of the clamp has allowed for seamless integration into the existing production line. This has led to a smoother workflow and a significant reduction in energy consumption.

When compared to other similar products on the market, Dalian Tiding's Motorized Slab Clamp shines. Competitor A's clamp can only handle a maximum weight of 300 tons, while our product can handle up to 550 tons. Competitor B's device has a much larger footprint, which limits its maneuverability in tight spaces.

Moreover, our clamp offers a more user - friendly interface and requires less maintenance, resulting in lower long - term operating costs. In a cost - benefit analysis, our product outperforms the competition by up to 40%.

Dalian Tiding's Motorized Slab Clamp is the ideal solution for steel producers looking to enhance the efficiency and safety of their transportation operations. It combines advanced technology, a compact design, and a proven track record of success.

Don't miss out on this opportunity to revolutionize your steel transportation. Contact us today to learn more about how our Motorized Slab Clamp can transform your business!