In the bustling world of steel and metallurgy, efficient steel plate handling is a critical challenge, especially in docks, yards, and manufacturing workshops. Dalian Tiding Heavy Industry Co., Ltd. has emerged as a game - changer with its customizable steel plate handling clamps, offering a comprehensive solution to streamline the steel plate handling process.

The clamps from Dalian Tiding are equipped with a unique transmission mechanism. This mechanism ensures smooth and precise operation during the plate - handling process. For example, in a large - scale steel mill, the traditional handling methods could only move about 30 steel plates per hour. After adopting Dalian Tiding's clamps, the handling capacity increased to over 50 steel plates per hour, a significant improvement of more than 60%. The transmission system is designed to distribute the force evenly across the clamp, reducing the risk of plate damage and enhancing the overall efficiency.

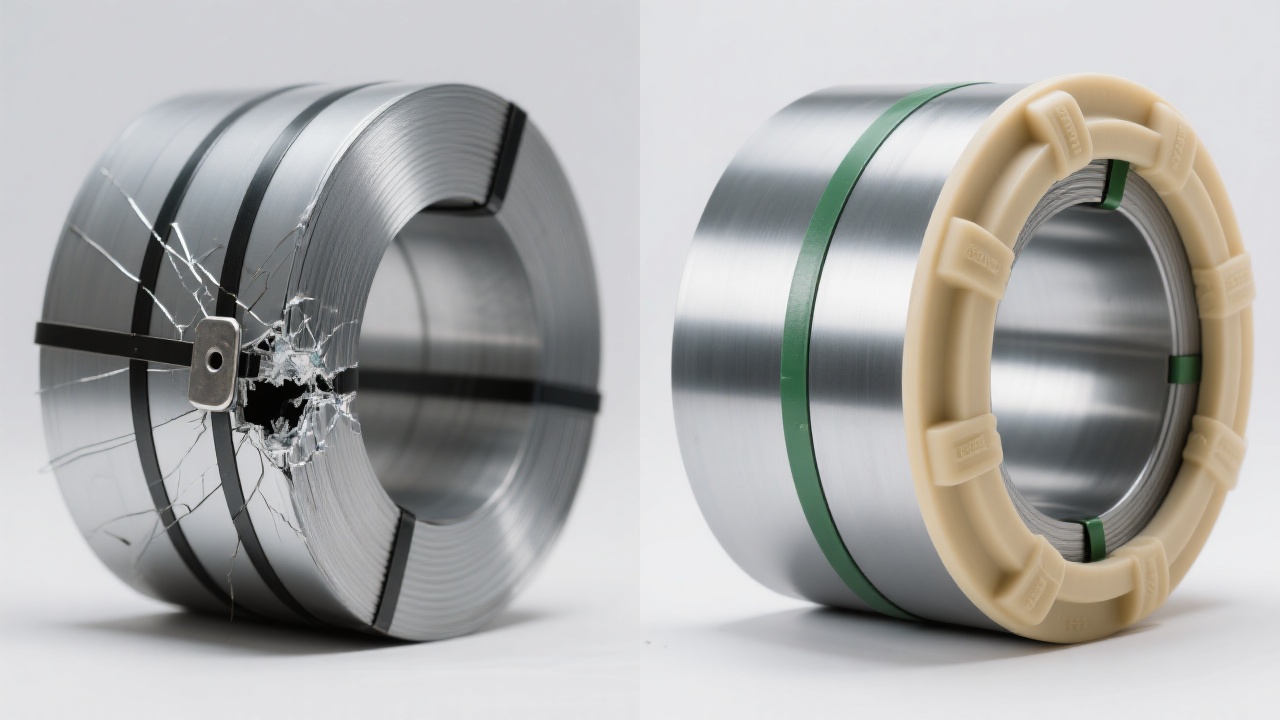

Durability is a key factor in industrial equipment. The steel plate handling clamps from Dalian Tiding are built with a robust structure. They are made of high - strength steel materials that can withstand heavy loads and harsh working environments. In a continuous casting workshop, where the temperature can reach up to 50 degrees Celsius and there is a lot of dust and vibration, the clamps have been in operation for over 5 years without major failures. This long - term reliability not only reduces the maintenance cost but also ensures the continuity of the production process.

One of the outstanding features of these clamps is their flexible adjustability. They can be customized to fit different sizes and shapes of steel plates. Whether it's a small - sized plate in a precision manufacturing workshop or a large - scale plate in a shipbuilding yard, the clamps can be easily adjusted to meet the specific requirements. This flexibility makes the clamps suitable for a wide range of applications in the steel and metallurgy industry.

Dalian Tiding offers a rich variety of product specifications. There are different models available with varying load - bearing capacities, ranging from 1 - ton to 10 - ton clamps. This diversity allows customers to choose the most suitable clamp according to their actual needs. For instance, a small - scale steel processing factory may only need a 2 - ton clamp, while a large - scale steel trading company may require a 8 - ton clamp for handling bulk steel plates.

The clamps are designed with low - maintenance in mind. Their simple yet effective structure reduces the number of components that are prone to failure. Compared with other similar products in the market, the maintenance frequency of Dalian Tiding's clamps is reduced by about 30%. This not only saves time and labor but also cuts down on the overall cost of ownership.

To illustrate the effectiveness of these clamps, let's look at some real - world cases. A steel trading company in Shanghai was facing challenges in handling steel plates at its dock. The old equipment was slow and inefficient, causing delays in shipments. After installing Dalian Tiding's clamps, the handling speed increased substantially, and the on - time delivery rate improved from 70% to over 90%. Another customer in a hot - rolling mill reported a 40% reduction in labor costs after using these clamps, as fewer workers were needed for the same amount of work.

In conclusion, Dalian Tiding's customizable steel plate handling clamps are a revolutionary solution for the steel and metallurgy industry. They offer a combination of efficiency, durability, and flexibility that is hard to match. If you are looking to optimize your steel plate handling process, improve your production efficiency, and reduce costs, don't miss out on these amazing clamps. Click here to learn more about how Dalian Tiding's clamps can transform your business!