In the aluminum processing industry, the transportation of aluminum ingots has long been a critical yet challenging link. Aluminum ingots are prone to sliding and damage during transportation, which not only leads to product quality issues but also increases logistics costs. According to industry statistics, about 10% - 15% of aluminum ingots experience varying degrees of damage during transportation, and the cost of loss caused by sliding and damage accounts for about 8% - 12% of the total transportation cost. Therefore, there is an urgent need for an effective solution to improve the safety and efficiency of aluminum ingot transportation.

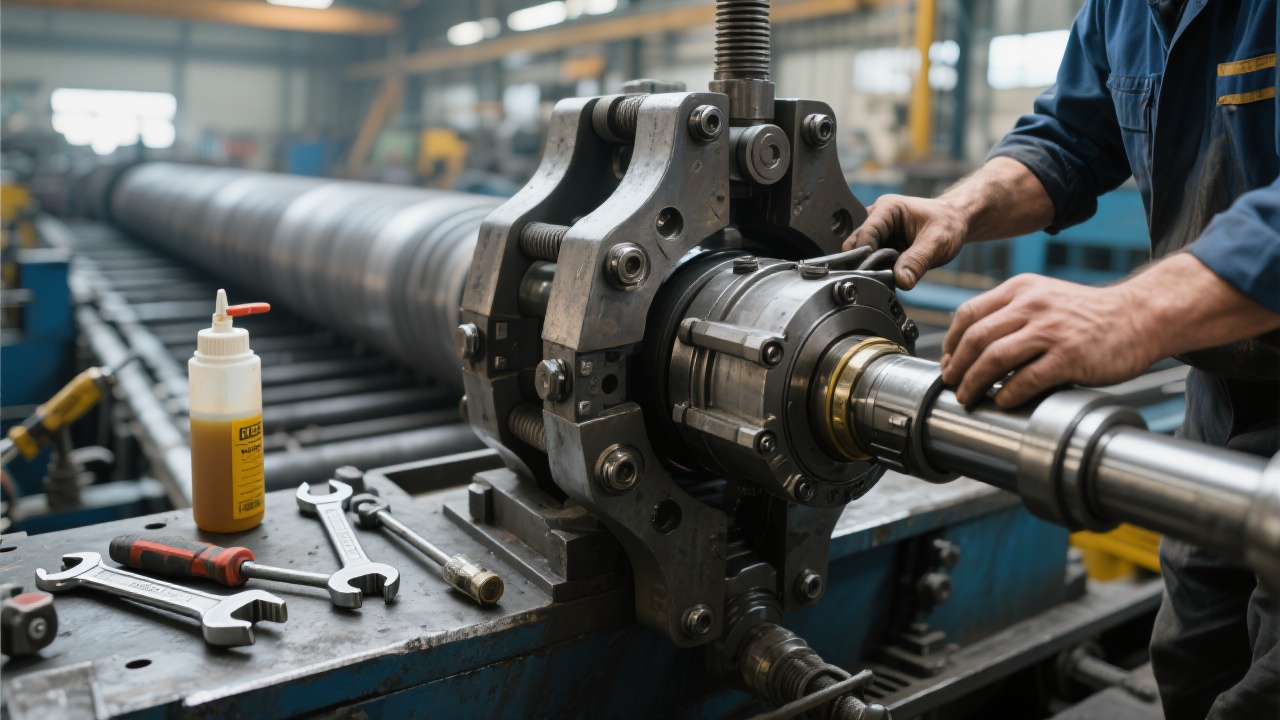

The hydraulic aluminum ingot clamps developed by Dalian Tiding Heavy Industry feature a scientific and reasonable structural design. The overall structure is compact, which can effectively reduce the space occupied during operation and improve the utilization rate of the transportation space. The clamping mechanism is designed with a special arc - shaped structure, which can better fit the shape of aluminum ingots and ensure a stable clamping effect.

These clamps are made of high - strength alloy materials, which have excellent mechanical properties such as high strength, high toughness, and wear resistance. The material can withstand high - intensity clamping forces and long - term use without deformation or damage. Tests show that the service life of these clamps is at least 3 - 5 years longer than that of ordinary clamps, which significantly reduces the replacement frequency and maintenance cost.

The clamping mechanism of these clamps adopts advanced hydraulic technology. The hydraulic system can accurately control the clamping force, ensuring that the aluminum ingots are firmly clamped without being damaged. Compared with traditional mechanical clamping methods, the hydraulic clamping mechanism has the advantages of faster response speed, more stable clamping force, and higher safety. The clamping force can be adjusted according to the size and weight of the aluminum ingots, with a maximum clamping force of up to 50 tons, which is suitable for various types of aluminum ingot transportation.

The hydraulic aluminum ingot clamps are highly adaptable in multiple industrial fields. In the aluminum smelting industry, they can be used for the handling and loading of aluminum ingots in the workshop, improving the production efficiency. In the aluminum product manufacturing industry, they can ensure the safe transportation of semi - finished and finished products. In the logistics industry, they can enhance the safety and efficiency of long - distance transportation of aluminum ingots.

Taking an aluminum product manufacturing enterprise as an example, after using these clamps, the internal handling time of aluminum ingots in the workshop has been reduced by about 30%, and the production efficiency has been significantly improved. At the same time, during the transportation process, the damage rate of aluminum ingots has decreased from about 12% to less than 2%, greatly reducing the loss cost.

A European aluminum processing enterprise had been troubled by the high damage rate of aluminum ingots during transportation. After using the hydraulic aluminum ingot clamps of Dalian Tiding Heavy Industry, within three months, the damage rate of aluminum ingots decreased from 15% to 3%, and the transportation efficiency increased by about 40%. The annual cost savings reached about 200,000 euros.

| Features | Dalian Tiding Hydraulic Aluminum Ingot Clamps | Competitor Products |

|---|---|---|

| Clamping Force | Up to 50 tons, adjustable | Generally 20 - 30 tons, less adjustable |

| Material | High - strength alloy, long service life | Ordinary steel, shorter service life |

| Structural Design | Compact, special arc - shaped clamping mechanism | Relatively bulky, less scientific clamping mechanism |

From the above comparison, it can be seen that Dalian Tiding's hydraulic aluminum ingot clamps have obvious advantages in terms of clamping force, material, and structural design, which endows them with strong market competitiveness.

Are you looking for a reliable solution to improve the safety and efficiency of aluminum ingot transportation? Dalian Tiding Heavy Industry's hydraulic aluminum ingot clamps will be your best choice. 立即了解如何提升您的铝锭处理效率 (Click here to immediately learn how to improve your aluminum ingot handling efficiency). Visit our official website or contact us for detailed information.