Electric screw drive coil clamps have become a preferred choice in the metallurgy industry for efficient and safe handling of steel coils. These advanced clamping systems are designed to enhance productivity while ensuring the safety of both equipment and personnel. This article delves into the working principle, technical parameters, and practical applications of these high-performance coil clamps.

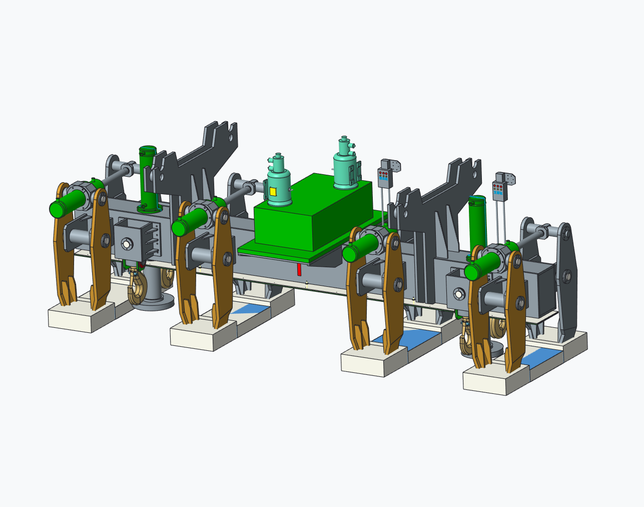

Electric screw drive coil clamps operate based on a simple yet highly effective mechanism. The core component is an electric motor that drives a screw system, which in turn controls the opening and closing of the clamping jaws. This system allows for precise control over the clamping force, ensuring a secure grip on the steel coil without causing damage to the surface or structure.

The design also incorporates a gravity-assisted operation, making it easy for operators to open and close the clamp with minimal effort. This feature not only improves efficiency but also reduces operator fatigue during long working hours.

To fully understand the capabilities of electric screw drive coil clamps, it's essential to review their key technical parameters:

| Parameter | Specification |

|---|---|

| Clamping Force | Up to 50 kN |

| Operating Voltage | 24V DC / 220V AC |

| Weight Capacity | Up to 10 tons |

| Adjustable Jaw Width | From 300 mm to 1200 mm |

| Protection Class | IP54 |

In a leading steel production plant in Southeast Asia, the implementation of electric screw drive coil clamps significantly improved operational efficiency. Before the upgrade, the facility relied on manual clamping systems, which were time-consuming and prone to errors. After replacing the old equipment with electric screw drive coil clamps, the company reported a 40% increase in lifting speed and a 60% reduction in product damage incidents.

This case highlights the practical benefits of using advanced coil clamps in real-world industrial environments.

Compared to traditional mechanical or hydraulic clamping systems, electric screw drive coil clamps offer several advantages:

Q: Are these clamps suitable for all types of steel coils?

A: Yes, they are designed to accommodate a wide range of coil diameters and weights, thanks to the adjustable jaw width and robust construction.

Q: Can the clamps be integrated with existing lifting systems?

A: Absolutely. The electric screw drive system is compatible with most overhead cranes and hoists, ensuring seamless integration into your workflow.

Electric screw drive coil clamps represent a significant advancement in material handling technology. Their combination of precision, durability, and ease of use makes them an ideal solution for modern metallurgical operations. Whether you're looking to improve efficiency, reduce downtime, or ensure safer handling of steel coils, these clamps deliver measurable results.

Ready to upgrade your material handling process? Contact us today to learn more about our electric screw drive coil clamps and how they can benefit your business.